Hammer-IMS kindly invites you to the upcoming Belgian event (co-organized by Hammer-IMS) where Technical and Product Manager Tom Redant will speak. The event includes short presentations related to innovative measuring techniques for coatings and a visit of the Hammer-IMS facilities.

Our new CURTAIN integrates a next-generation up to 4.5 meter mechanical frame equipped with multiple sensors based on our clean M-Ray based measurement technology. The solution is developed to perform 24/7 quality control on inline production of plastic films, nonwovens, fabrics, etc. The new Marveloc-CURTAIN solution entails product improvements covering proprietary mechanical frame, M-Ray sensors, and Connectivity software.

Let’s meet Robin Michiels, our new sales and business developer. His experience gained at ABB, Fabricom and Elia enables him to further develop Hammer-IMS sales operations across Europe. Welcome Robin! He introduces himself in the interview below.

The coming months, Hammer-IMS will cross Germany for speaker assignments or tabletop exhibits in leading conferences. The tour consists of textiles, nonwovens or plastics related events targeting material research, inline manufacturing and quality inspection. The first stops on the tour are Berlin - Textile Coating and Laminating (TCL) conference – and Hof - Hofer Vliesstofftage – both taking place simultaneously.

October 1st, 2017, between 10:00 AM and 5:00 PM

The 9th edition of the Textile Coating & Laminating Congress: ‘Re-invent the Textile Coating and laminating Industry of Tomorrow’ takes place in Ghent Belgium on September 28-29 2017.

The industry-leading German magazine C2 featured the application story of Hammer-IMS successfully contributing to the production quality at ANL Plastics. The international producer of thermoformed plastic packaging – uses a Marveloc-CURTAIN measurement system from Hammer-IMS in its production facilities in Wellen, Belgium. The system contains four M-Ray sensors, continuously measuring the plastic thickness on an ANL Plastics production machine. ANL Plastics experiences the technology of Hammer-IMS as fast, robust, secure, ecologic and easy-to-install. Stefan Tielen, CEO ANL Plastics: "The disruptive technology of Hammer-IMS fits our strategy to play a leading role in downscaling the widespread use of X-ray and nuclear measuring systems in our sector.

The Hofer Vliesstofftage (8 - 9 November 2017) is the main event for technical innovations in the nonwoven industry.

ANL Plastics – an internationally renowned producer of thermoformed plastic packaging – is now using equipment from Hammer-IMS in its production facilities in Wellen, Belgium. Hammer-IMS, a joint start-up from KU Leuven University Belgium and LRM Belgium, recently delivered its Marveloc-CURTAIN measurement system to the packaging producer. The system contains four M-Ray sensors, continuously measuring the plastic thickness on an ANL Plastics production machine. ANL Plastics experiences the technology of Hammer-IMS as fast, robust, secure, ecologic and easy-to-install. The technology is considered as a potential game-changer for the plastic packaging market, since Hammer-IMS products do not use nuclear energy.

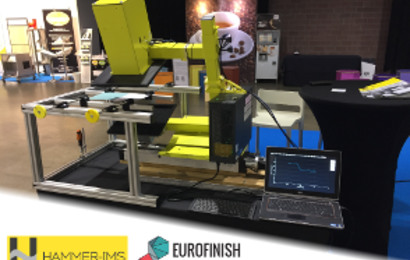

Hammer-IMS shows a contactless coating thickness measurement at Eurofinish in Haasrode Belgium the coming days. Our CURTAIN-demo setup shows how we can provide clean solutions for contactless coating thickness measurement, e.g. for textile coatings. Come and discuss your project with us even it requires ATEX certification. www.eurofinish.be.

Multiple heads enable high material coverage! Watch the animation!

Last month, Hammer-IMS presented itself in C-mine where policy makers from Limburg province discussed with University Leuven the entanglement of Limburg and Leuven on the level of innovation.