We are happy to be featured in the Belgian Trends magazine. The article highlights our radar technology, which is a clean alternative for nuclear and radioactive measuring systems. Our M-Ray measuring solutions measure the basis-weight of nonwovens, fabrics, etc. and the thickness of plastics sheets and films. The solutions even support inline coating weight measurement of opaque materials, where X-Ray systems may fail.

Click here to check out the Hammer-IMS article in Trends magazine (Dutch language):

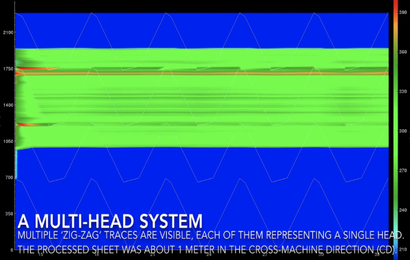

At Hammer-IMS we are proud to be an innovative company that evolves continuously. The new Color Graph development in our software visualizes measurements in both machine direction and cross-machine direction.

The 30 centimeter standoff distance on non-nuclear Hammer-IMS basis-weight measuring system is unique in the market. High standoff is perfect to monitor basis-weight across nonwovens production lines – from thick base materials to thin nonwovens ready for shipment. Check out the video below:

This short video shows a few simple experiments explaining why M-Ray technology is a perfect fit for inline coating weight measuring. Opaque materials such as bariumsulphate, titaniumdioxide or calciumcarbonate do not limit the applicability of the technology. M-Ray technology therefor has a significant advantage compared to X-Ray technologies.

Hammer-IMS will tour across exhibitions in Europe in Winter & Spring 2019.

Hammer-IMS has successfully delivered a contactless and clean device for measuring the basis-weight of felts and woven products to Heimbach. The milestone of successful application of Hammer-IMS’s M-Ray technology in the specific application domain of Heimbach consolidates the position of non-nuclear and non-radioactive gauges in the nonwoven and textile sector.

Hammer-IMS has developed a new range of C-frames for inline measuring tasks. The C-frame technology enables application of one ore more M-Ray measuring heads. C-frames are more flexible compared to O-frames and work on a broad range of production line widths. The high stand-off distance of our C-frame systems gives a new dimension to the concept of contactless measuring, even for very thick materials exceeding multiple centimeters. Click the video for a quick introduction...

Last month, Bart Goossens took on the role of senior R&D engineer. Building on experience with Option, Barco and Philips, he brings valuable engineering skills on hardware and software levels. Bart will contribute in optimizing the industrialization for the full range of innovative Hammer-IMS systems.

Hammer-IMS has participated in a range of events in Rome, Chemnitz and Cologne.

After completing our tour across Germany, Hammer-IMS exhibits on EDANA in Rome and mtex+ in Chemnitz. At the same time, CEO Noël Deferm speaks on the Chemnitzer Textil Tagung.

Hammer-IMS supports its extended reach in fabrics and nonwovens markets by playing an active role on events in Rome, Chemnitz and Cannes.

French nonwoven producer uses a clean Marveloc-CURTAIN for inline basis-weight quality control of felts & nonwovens