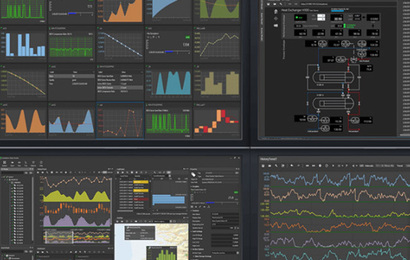

Bringing industrial data safely and in real-time to remote IT infrastructures has always been challenging when working with classical technologies

We have published a new video on our machine's user software's features.

Orfit Industries executes extrusion quality control of engineered thermoplastic sheets with inline Hammer-IMS measuring system.

The innovative thickness measuring system of Hammer-IMS is exactly what Orfit Industries in Antwerp needs for its high-temperature thermoplastic extrusion line. Medical specialists worldwide use Orfit’s thermoplastic sheets for orthotic and prosthetic purposes.

Sector leader DILO demonstrated Belgian Hammer-IMS on ITMA 2019 in Barcelona

Eli Keunen’s work at Hammer-IMS awarded at Thomas More college in Geel, Belgium

Internship students appreciate real project involvement and experience

DILO - a leading German producer of fully-integrated nonwoven production lines - will showcase a system of Hammer-IMS on ITMA 2019.

Every now and then, we give the word to one of our colleagues at Hammer-IMS. Today, Nele Reynders, Senior R&D Engineer, comments on the latest in measuring machine construction and measurement system integration.

Watch how to find Easter Eggs with Hammer-IMS technology!

In the videos below, Noël Deferm (General Manager) and Tom Redant (Technical Manager) look back on 2018 and comment on the on-going year 2019. Noël explains where Hammer-IMS stands as a company whereas Tom focuses on technology and product developments.

Hello, I am Robin Michiels, your sales contact person for Hammer-IMS. You have probably heard about our M-Ray radar technology. It is a clean alternative for nuclear and radioactive measurement systems in production lines. Our M-Ray solutions measure the basis-weight or thickness of all kinds of flat materials – like nonwovens, fabrics, paper, plastics sheets or films.

Hello, my name is Bram Iliaens. Recently, I joined Hammer-IMS as product and development engineer.