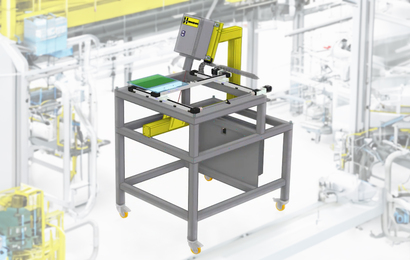

Discover the accuracy and precision of Hammer-IMS' 2D Scanner Demo Machine and its exceptional performance at various industry fairs. Visitors at ITMA Milan 2023 were able to experience firsthand the cutting-edge technology that has revolutionized quality control processes across multiple sectors. The revolutionary 2D-scanner is designed for unparalleled 100% inspection and measurement of basis-weights.

After INDEX in Geneva last November, Hammer-IMS resumed its exhibition tour across Germany in Winter & Spring 2022. Many people came and visited us to watch one of our non-nuclear inline thickness and basis weight measuring systems in action! For example, the sleek and slim C-frame based system proves to be ideal for quality control of foils and films as well as coatings, paper, fabrics, textiles and nonwovens.

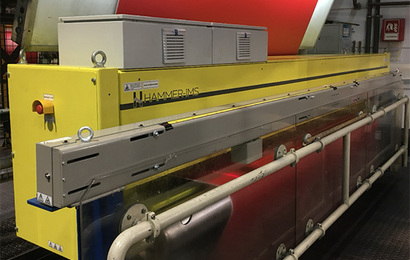

With many international system installations taking place, we want to point out that the design, delivery and installation process of your order is in good hands. Your purchase with Hammer-IMS is a smart move, not only while we are working to deliver your shiny yellow machine on time but also when the machine will be running at your facility in your production line of choice.

Known for the world's most advanced fabric technologies, Low & Bonar creates versatile materials in smart combinations to deliver performance. Since May 2020 part of German Freudenberg Performance Materials, Low & Bonar Hückelhoven is a pioneer in the technical textiles group. "The first purchased installation within the Low & Bonar has been running now for more than 10 months here in Hückelhoven, Germany," says Plant Manager Henk Hoekstra.

Due to the covid-19 pandemic, most international expos of 2020 are canceled or postponed. Therefore, we are setting up a new lineup of events for 2021 to be able to meet you in person and discuss your specific QC applications.

Our disruptive M-Ray technology is pure electronic by nature. This means that our non-nuclear measuring solutions are harmless for people and the environment. Completely safe for operators...

Started in January this year, Dirk Irle joined Hammer-IMS as a seasoned sales and business developer in the DACH region, Eastern Europe and Scandinavia. He has over 30 years experience in sales, marketing and technical support positions for a range of solution providers in measurement and engineering. Dirk has an engineering degree in computer science.

DILO - a leading German producer of fully-integrated nonwoven production lines - will showcase a system of Hammer-IMS on ITMA 2019.

Every now and then, we give the word to one of our colleagues at Hammer-IMS. Today, Nele Reynders, Senior R&D Engineer, comments on the latest in measuring machine construction and measurement system integration.

Hello, I am Robin Michiels, your sales contact person for Hammer-IMS. You have probably heard about our M-Ray radar technology. It is a clean alternative for nuclear and radioactive measurement systems in production lines. Our M-Ray solutions measure the basis-weight or thickness of all kinds of flat materials – like nonwovens, fabrics, paper, plastics sheets or films.

Hello, my name is Bram Iliaens. Recently, I joined Hammer-IMS as product and development engineer.

The 30 centimeter standoff distance on non-nuclear Hammer-IMS basis-weight measuring system is unique in the market. High standoff is perfect to monitor basis-weight across nonwovens production lines – from thick base materials to thin nonwovens ready for shipment. Check out the video below: