Major consumers of plastic sheet include cars, trucks, planes and trains, along with medical technology, building, construction and technical products. Typically, the terminology 'sheet' is used for plastic boards with thicknesses higher than 1 mm. Plastic structures with thicknesses less than 1 mm are referred to as 'films'. Packaging accounts for roughly half of all extruded plastics sheet, and much of that is thermoformed into the packages found at the supermarket. Rigid sheets are used in construction work: acrylic glass is well-known in football stadiums, polycarbonate for ski lift bubbles but also polyethylene for toy and leisure products.

Applications significantly differ by end-use, used polymer compounds, surface texture, additives, mechanical impact and bending properties, appearing crystal clear, totally opaque and every gradation in between. The differences are endless but all plastic converters face the same issue: raw material costs can get very high.

Hammer-IMS provides products for measuring sheet thicknesses while being extruded. We measure continuously, enabling you to optimize the usage of raw materials. Contactless measurement with high stand-off distance avoids scratches on your optical-grade sheets, also for sheet thicknesses up to several centimeters.

The plastics sheet extrusion industry is diversified. Hammer-IMS can measure a myriad of materials: PE (HDPE, LDPE), PP, PA, ABS, EVA, PMMA, PMP, PC, PE, PPS, PVC, PVDF, PET, The plastic sheet applications vary by end use, material (or multiple materials), surface texture, material rigidity, appearing crystal clear, totally opaque and every gradation in between — the differences are endless.

Thermoplastic elastomers (TPE), sometimes referred to as thermoplastic rubbers, are a class of copolymers or a physical mix of polymers (usually a plastic and a rubber) that consist of materials with both thermoplastic and elastomeric properties. Hammer-IMS can both measure the thickness of both thermosets and thermoplastics. For instance, thermoplastic olefins (TPO) are increasingly used as a roofing material. TPEs are also widely used for catheters where nylon copolymers offer a range of softness ideal for patients.

The plastics conversion industry is highly-automated. Check out our technology section to find out which control loops Hammer-IMS can assist you with. Overall, The M-Ray based measuring solutions of Hammer-IMS offer lower total cost of ownership (TCO) compared to conventional nuclear and radioactive measuring technologies. This is good news for manufacturers with the ambition to equip their production lines with faster and more accurate quality control.

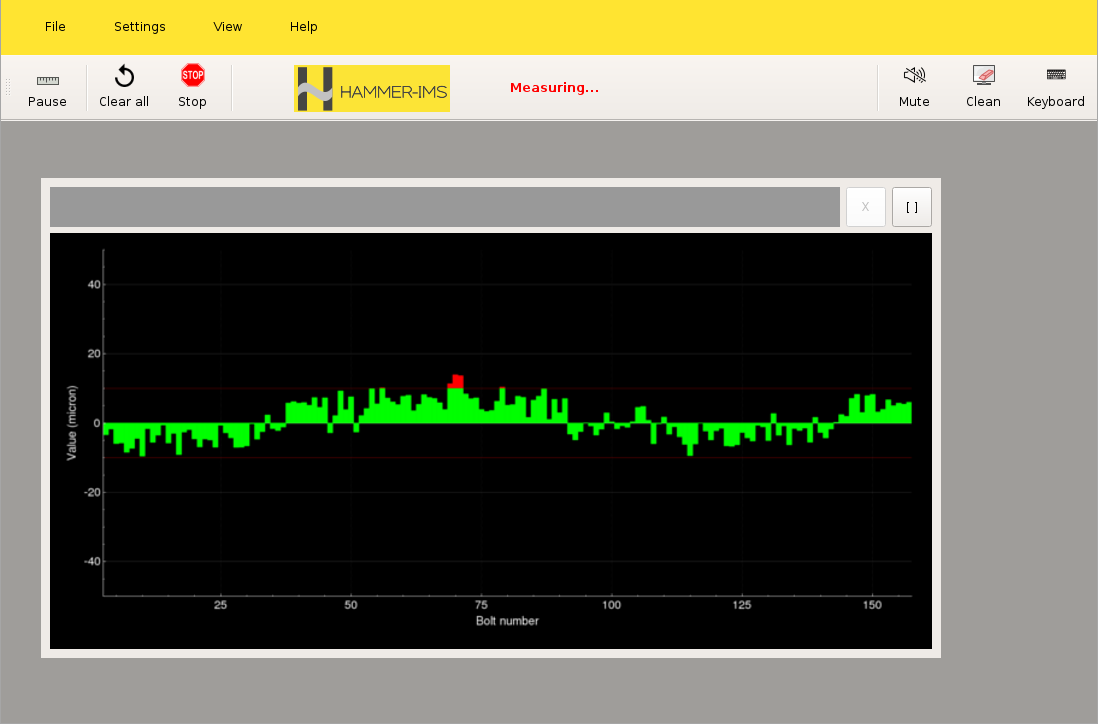

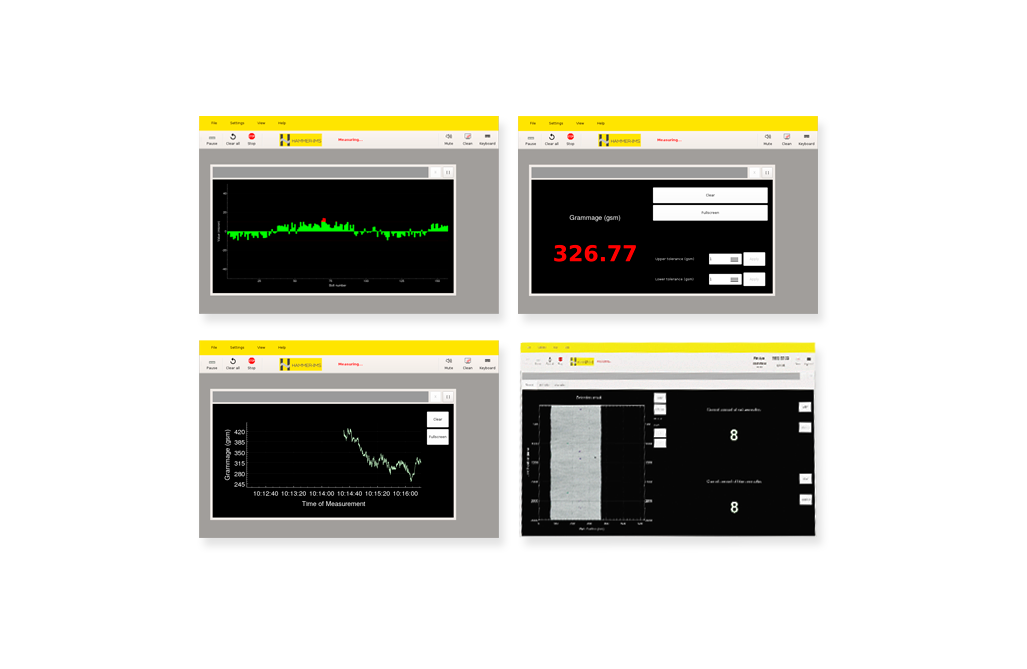

Plastic sheet manufacturers can decide on the width of the CURTAIN frame and the number of integrated measuring units. This way, the solution supports high-width production and situations where quick feedback is required. The Marveloc-CURTAIN solution measures material up to 30 centimeters thick, and uses one or more fixed or traveling sensors for maximum coverage in cross-machine direction. This enables the system to detect local deviations that are likely to correspond to individual screwing bolts of the extrusion die. Our software Connectivity 3.0 supports bolt mapping as shown in the screenshot below.

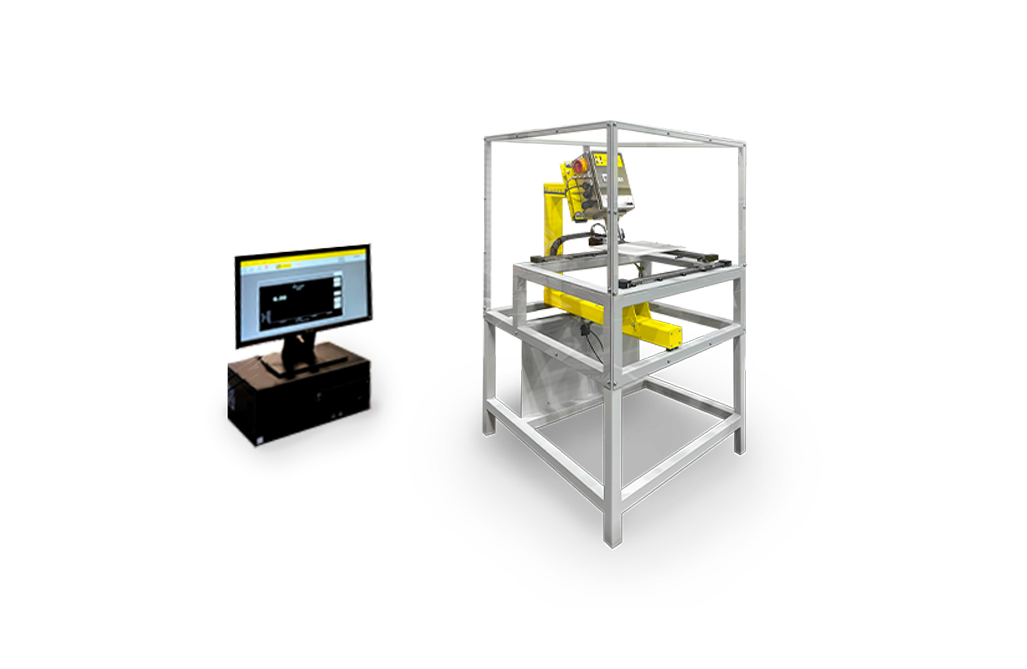

Based on studies, trials and customer feedback, Hammer-IMS could offer your company a reduction of the material thickness margin from 200 micrometer to 20 micrometer. Continuously saving 180 micrometer of material content, on average, leads to impressive financial savings. This means more than 1,000 metric tons of raw material that are saved in one year on a single 2-meter wide polycarbonate extrusion line that runs 24/7. A solution realizing this business case would look like the one as shown below.

The M-Ray based measuring systems of Hammer-IMS can be easily placed in a plastics extrusion line on the production floor. Typically, they are located between the cooling rollers and the cutter.

Surface inspection solution for detection of anomalies and defects

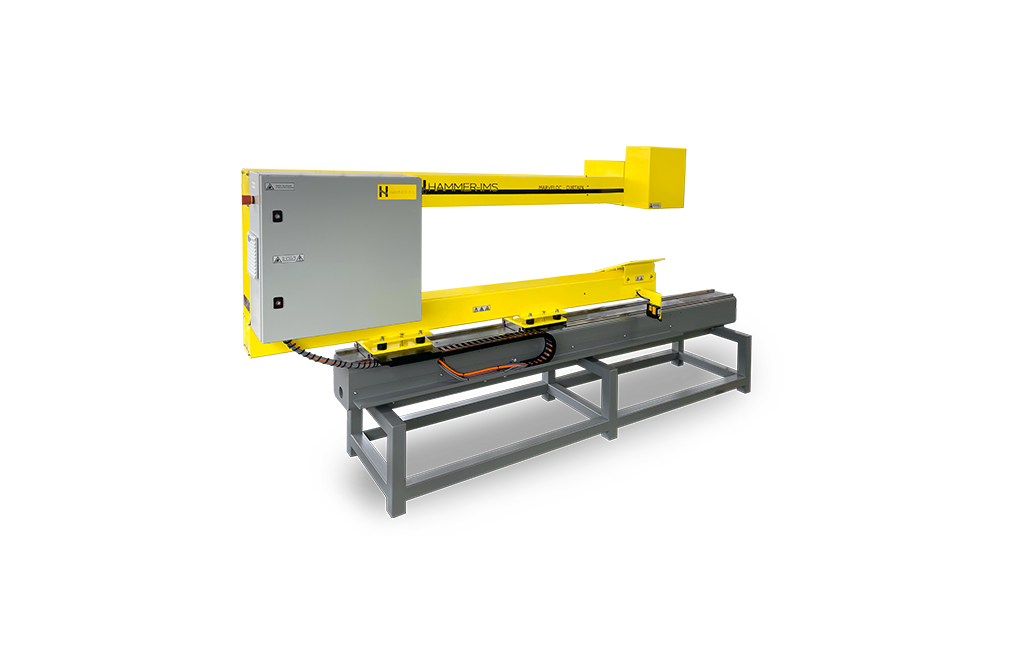

Machine for thickness measurement of flat materials

Machine for thickness measurement of flat materials

Machine for thickness measurement of flat materials

For OEM projects on thickness measuring by machine builders and sensor integrators

Machine for thickness measurement of flat materials

Industrial software to connect to PLC's and various information sources

Lab devices, custom or off-the-shelf