Connectivity 3.0 includes a range of integrated functionalities:

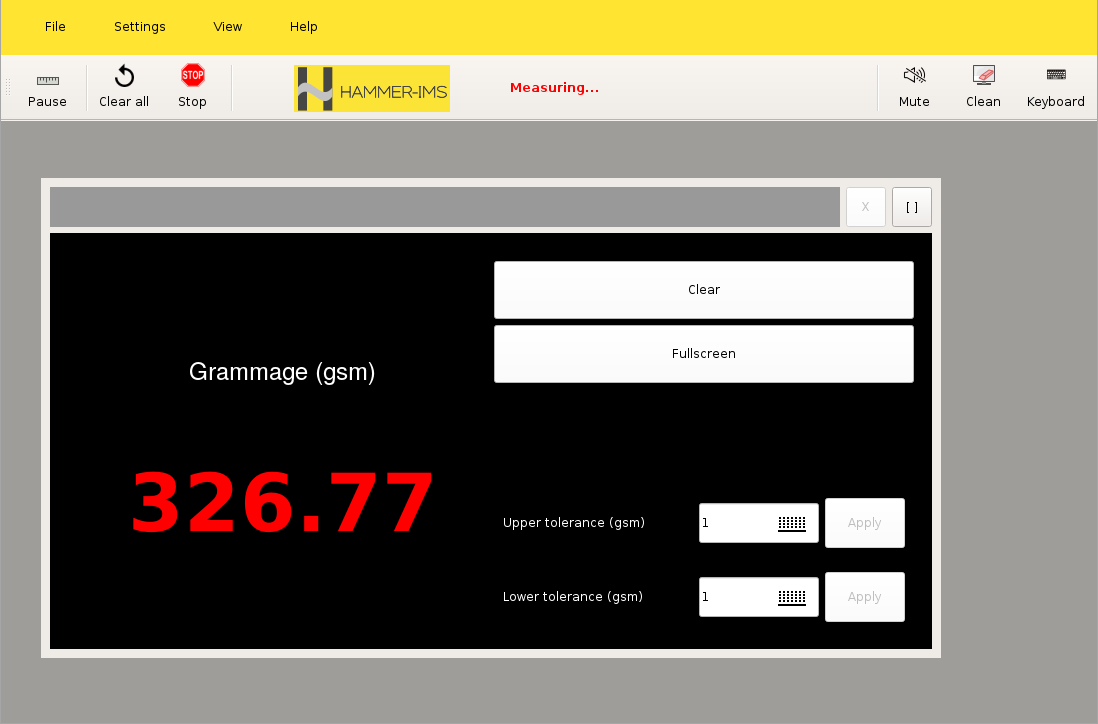

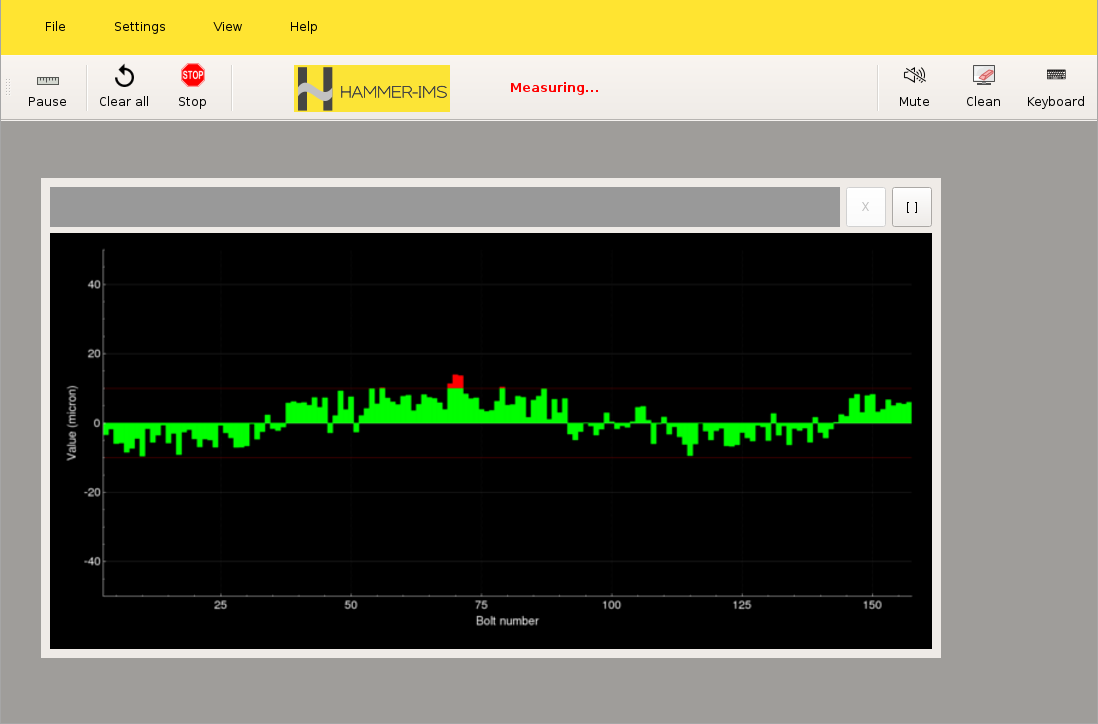

Our main software window only displays the features that really matter to our users. This is basically: a visualization (e.g. basis-weight as a numeric value), a Measure/Pause button, a Clear button and a Stop button. Furthermore, some buttons that are intended to make life easier: a Cleaning button (to disable the touch screen for 60 seconds to allow cleaning), a Keyboard button to show the touch keyboard and a Mute button to mute auditive alarms (e.g. a buzzer).

The flexible design of the software enables us to deliver tailor-made visualizations for your industry. An installation on a plastic extrusion line would probably ask for a plugin showing the thickness for each tuning bolt, whereas a plastic calendering line does not deal with tuning bolts and therefore requires another plugin on its turn.

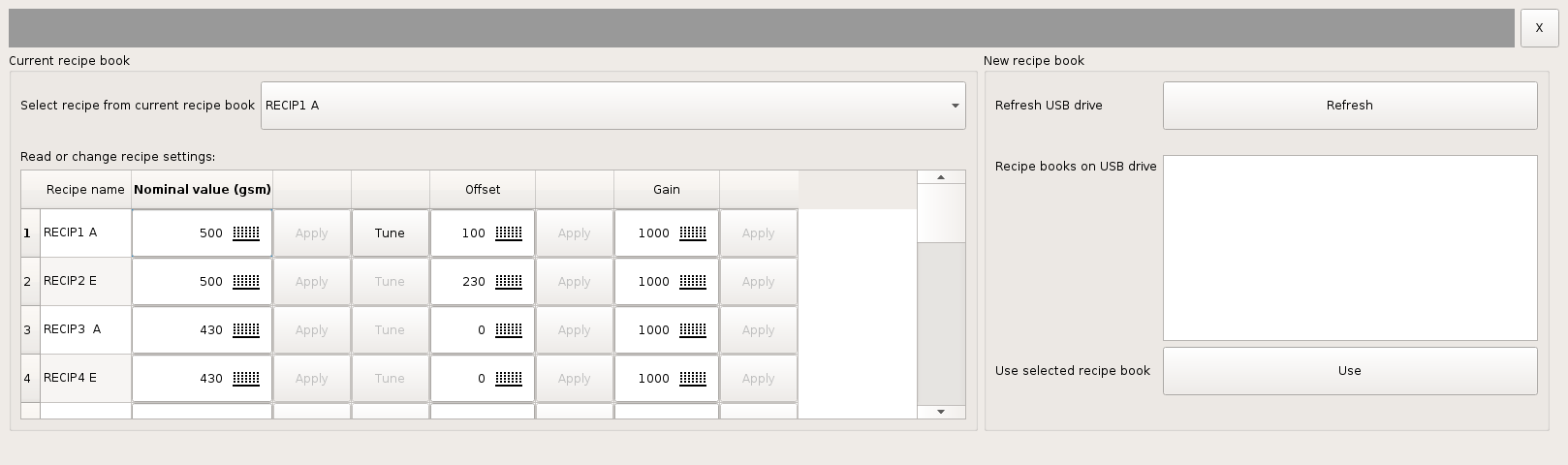

We do not need you to be an M-Ray professional to operate Hammer-IMS's measurement systems and Connectivity 3.0. The measurement system's configuration is pretty easy. We offer a single-click configuration of the software according to the recipe that is currently being processed/produced by your production equipment. Do not waste your precious time checking all configurations over and over again and do not let human mistakes or improper configurations be directly responsible for the quality of your products. Production managers can upload recipes from an Microsoft Excel-compatible file into Hammer-IMS's Connectivity software.

Connectivity 3.0 also delivers strong integration capabilities:

It can report measurement data directly to Microsoft SQL database servers or FTP/SFTP servers.

Optional Grafana dashboards can be shipped and configured, allowing customers to store and analyze historical data from their office environments over longer periods. Grafana furthermore provides attractive and interactive visuals. It enables report generation, integrated with the customer’s recipe and/or batch system. It can be made available on a remote server or straight from the Hammer-IMS HMI system. The system is connectable with PLC technologies such as Beckhoff and Siemens, via a Beckhoff-based bus coupler. Real-time feedback can be provided to the production process through Modbus TCP/IP server and OPC/UA software implementations. Feedback control is supported for both die and knife systems. Furthermore, PROFINET and Ethernet/IP are also supported via Beckhoff PLCs acting as ADS-PROFINET or ADS-Ethernet/IP bridges.

Check out the software walkthrough video. Make sure you enable the sub-titles in the video for a detailed explanation of the shown functionalities!

The software makes efficient use of the underlying computing power, making it an ideal choice for machine-vision tasks—this is achieved through implementation in the C++ language.