Edge-Vision-4.0-CURTAIN is a high-resolution inspection system that ensures reliable quality control across industrial production lines. Housed in rugged steel CURTAIN frames, it is engineered for long-lasting performance in both continuous and batch processing environments.

The system captures and analyzes detailed images of products and materials, allowing for fast and accurate detection and classification of surface defects. Its enclosed design blocks out external light interference, delivering consistent and precise inspection results even under challenging conditions.

With high-resolution imaging, adaptable configurations, and robust operation, Edge-Vision-4.0-CURTAIN is a powerful solution for manufacturers aiming to boost accuracy, efficiency, and process stability.

The Edge-Vision-4.0 platform supports multiple lighting techniques, essential for creating the right contrasts for every inspection task. You can optimize results by choosing between: Bright-field, Dark-field, and Transmission lighting.

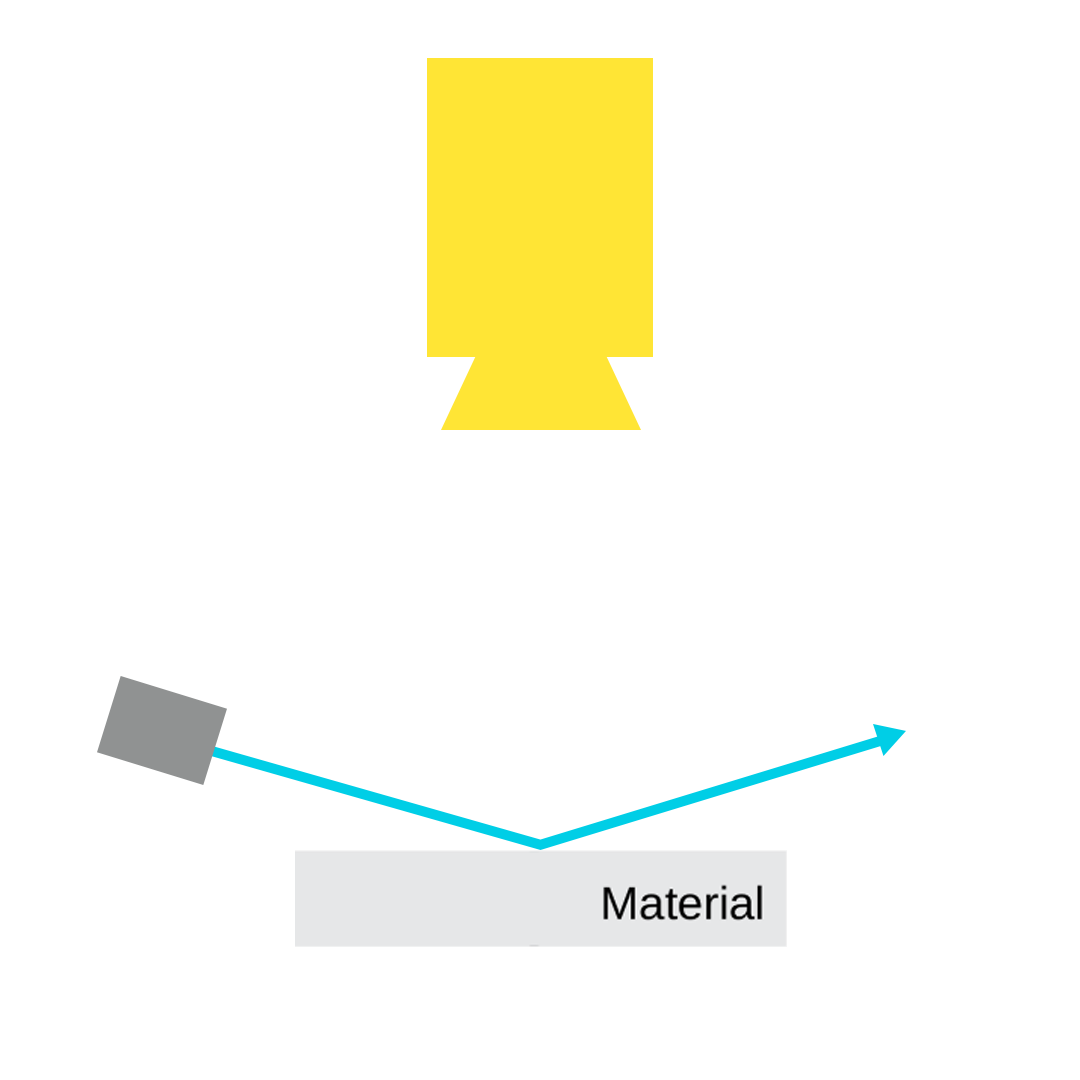

Bright-field lighting illuminates the object directly from above or the front, creating strong contrast on surface features and textures. It’s ideal for detecting surface defects, scratches or dirt on reflective or opaque materials.

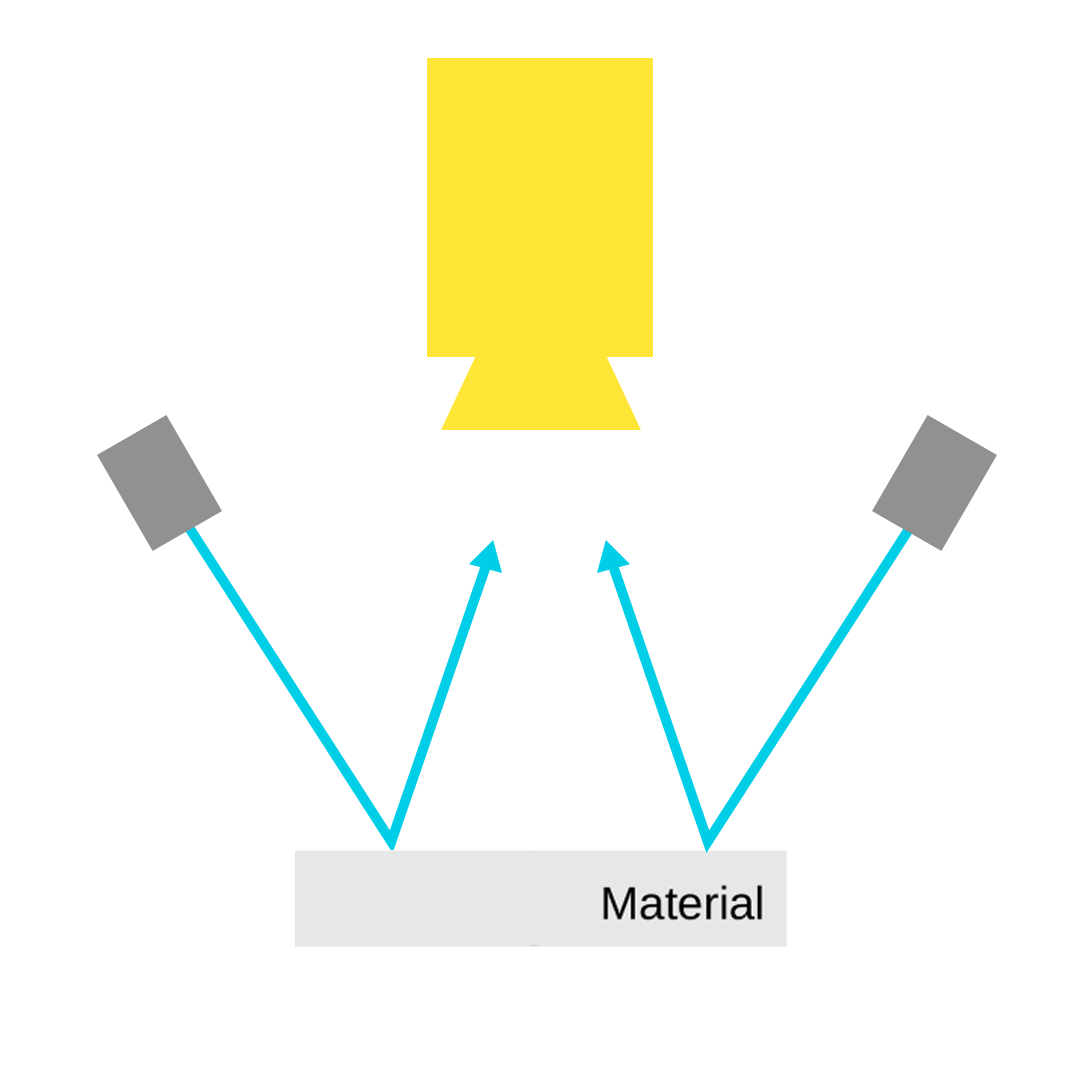

Dark-field lighting uses angled or side illumination, causing defects like scratches or bumps to scatter light differently than smooth surfaces. This highlights edges and surface irregularities with high contrast against a dark background, perfect for subtle surface inspection.

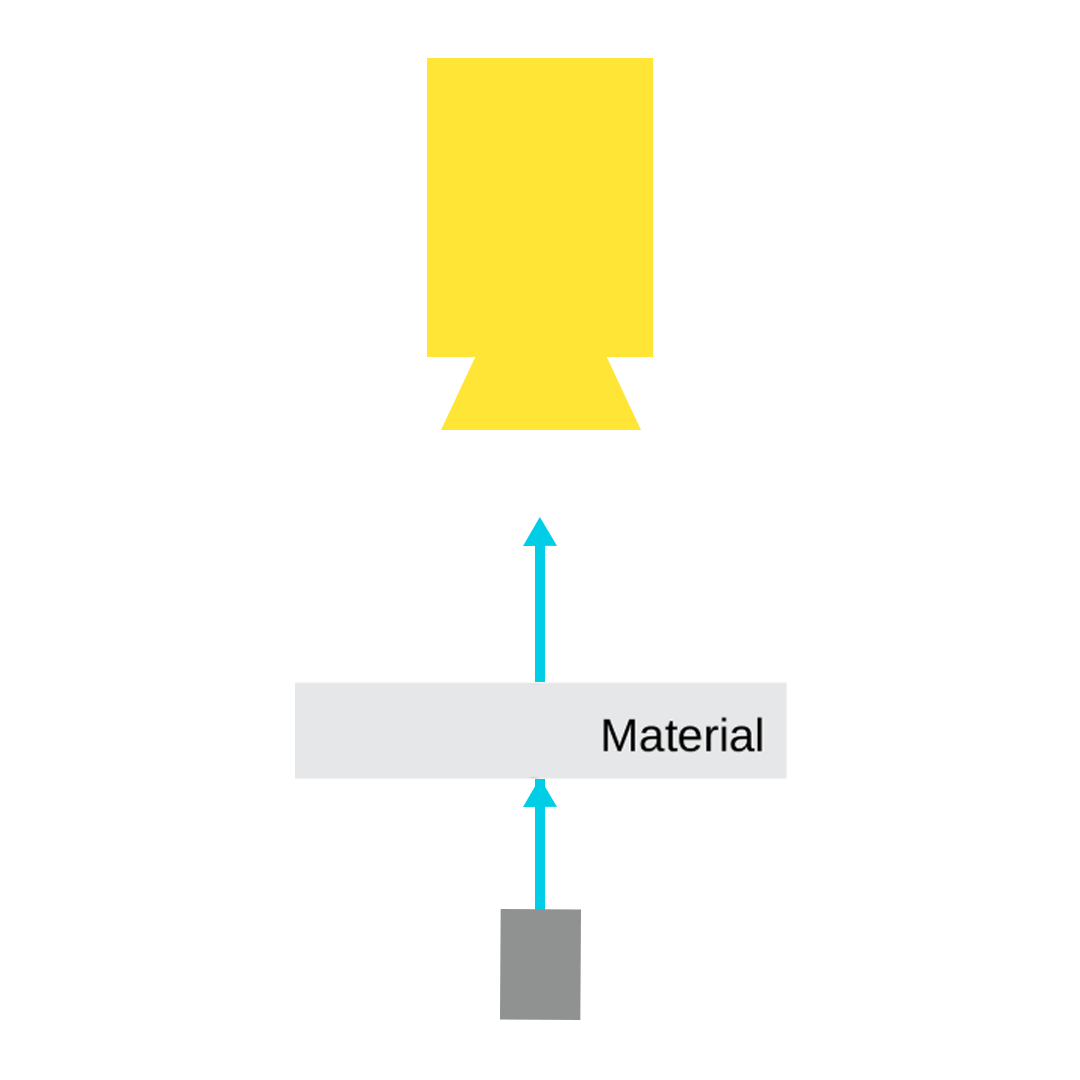

Transmission lighting illuminates the object from behind, allowing light to pass through transparent or semi-transparent materials. This method excels in inspecting holes, cracks, or inclusions in thin films, glass, plastics, or packaging materials.

The software environment for Edge-Vision-4.0 is called Connectivity 3.0. It provides a fully integrated quality control solution by combining different measurement tools within the same system. The software offers:

During production, each panel passes through the Edge-Vision-4.0-CURTAIN, where the system generates a complete 100% fingerprint of the panel. Inspection results are displayed instantly on the HMI and automatically stored for later use and analysis.

This is crucial for panel manufacturing, as it ensures consistent quality and helps detect defects at the earliest possible stage. By securing both process reliability and end-product quality, manufacturers can reduce waste, optimize efficiency, and guarantee customer satisfaction.