Edge-Vision-4.0-CURTAIN ist ein hochauflösendes Inspektionssystem, das eine zuverlässige Qualitätskontrolle entlang industrieller Produktionslinien gewährleistet. Untergebracht in robusten Stahl-CURTAIN-Rahmen, ist es für eine langlebige Leistung sowohl in kontinuierlichen als auch in Batch-Verarbeitungsumgebungen konzipiert.

Das System erfasst und analysiert detaillierte Bilder von Produkten und Materialien und ermöglicht so eine schnelle und genaue Erkennung und Klassifizierung von Oberflächenfehlern. Das geschlossene Design blockiert externe Lichteinflüsse und liefert so konsistente und präzise Inspektionsergebnisse, selbst unter schwierigen Bedingungen.

Mit hochauflösender Bildgebung, anpassbaren Konfigurationen und robustem Betrieb ist Edge-Vision-4.0-CURTAIN eine leistungsstarke Lösung für Hersteller, die Genauigkeit, Effizienz und Prozessstabilität steigern möchten.

Entdecken Sie alle unsere TechnologienChoosing the right lighting technique can improve defect detection, reduce false alarms, and ensure your inspection system delivers consistent, reliable results. The Edge-Vision-4.0-Curtain supports multiple lighting techniques, allowing you to optimize inspection results for a wide variety of applications:

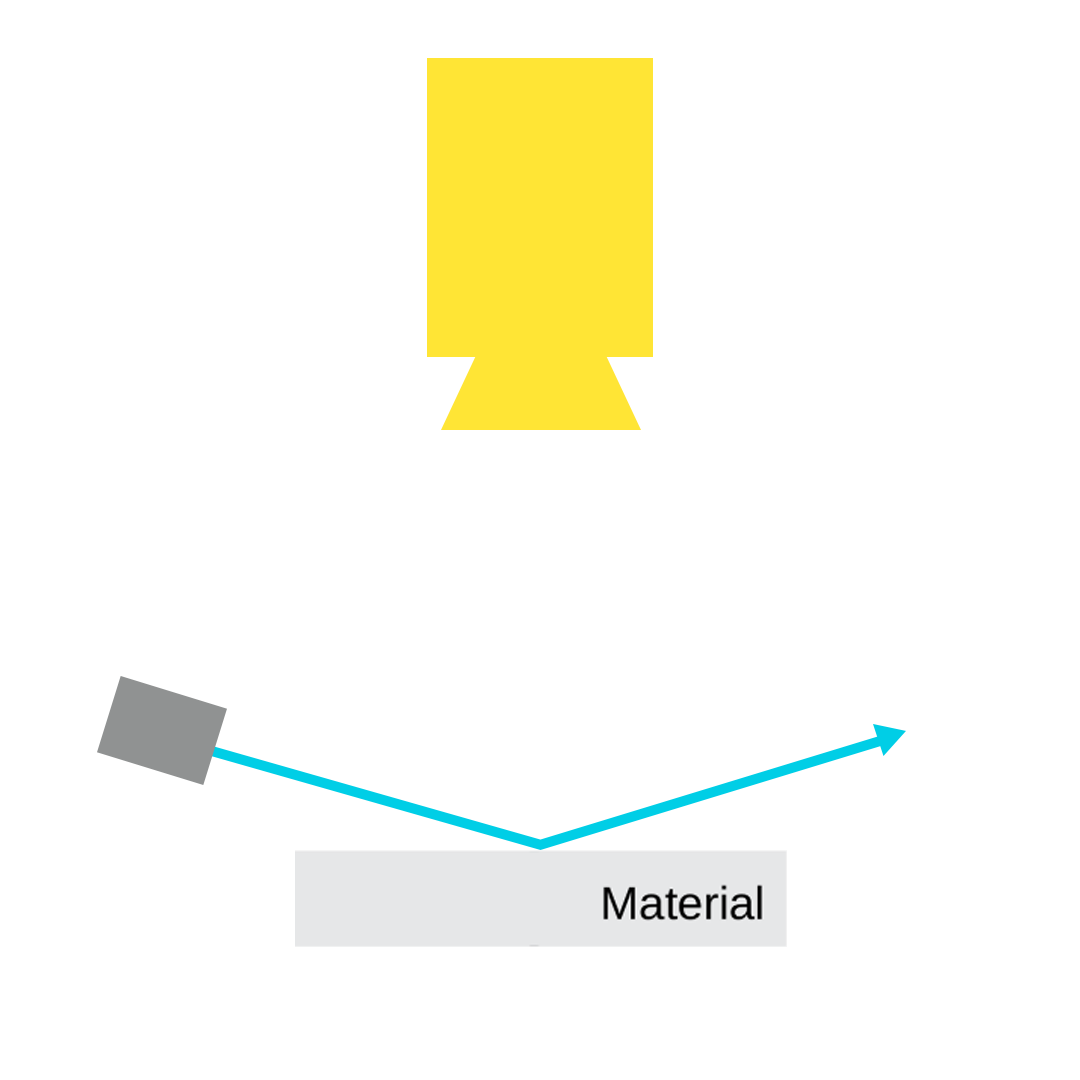

Bright-field lighting illuminates the object directly from above or the front, creating strong contrast on surface features and textures. It’s ideal for detecting surface defects, scratches or dirt on reflective or opaque materials.

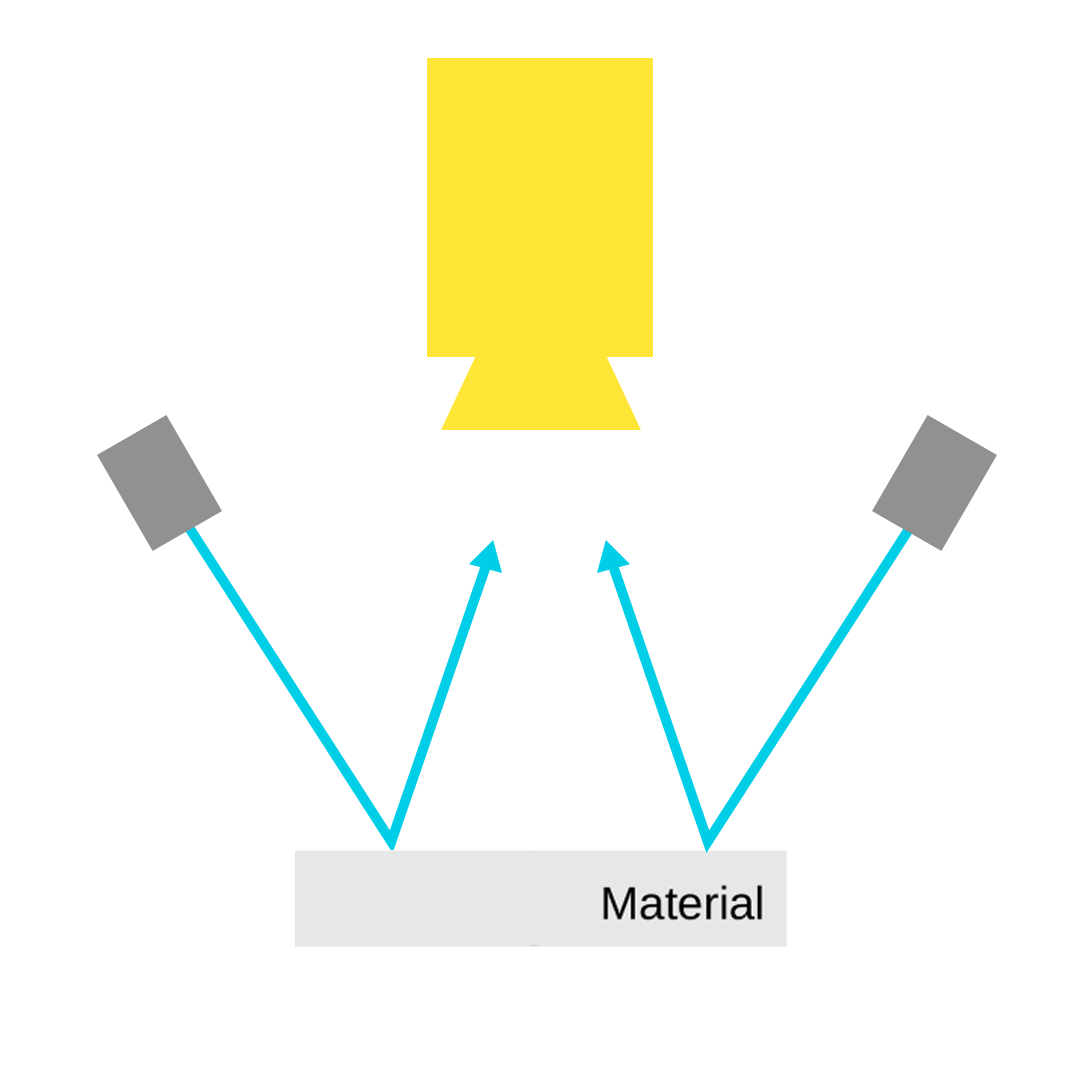

Dark-field lighting uses angled or side illumination, causing defects like scratches or bumps to scatter light differently than smooth surfaces. This highlights edges and surface irregularities with high contrast against a dark background, perfect for subtle surface inspection.

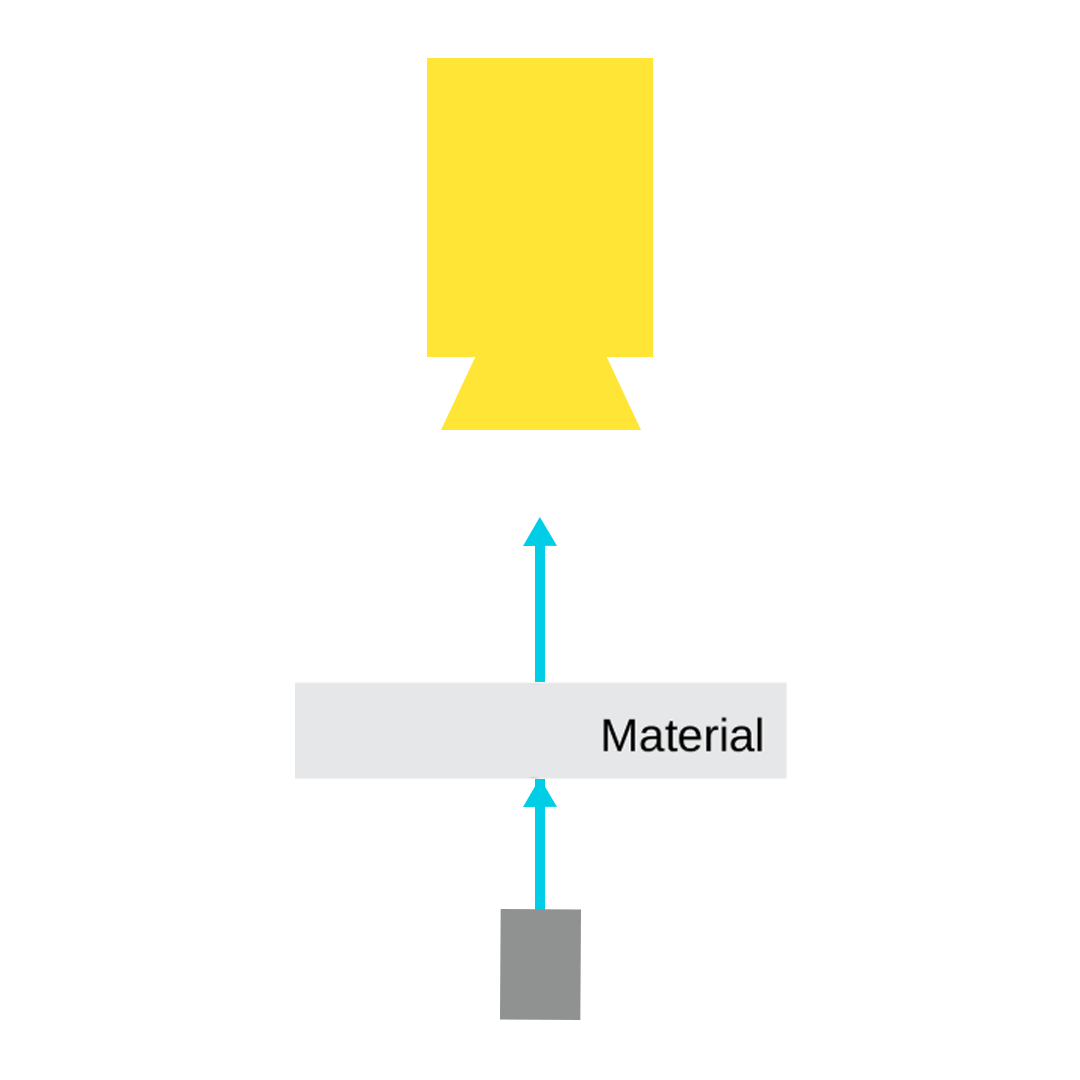

Transmission lighting illuminates the object from behind, allowing light to pass through transparent or semi-transparent materials. This method excels in inspecting holes, cracks, or inclusions in thin films, glass, plastics, or packaging materials.

The software environment for Edge-Vision-4.0 is called Connectivity 3.0. It provides a fully integrated quality control solution by combining different measurement tools within the same system. The software offers:

During production, each panel passes through the Edge-Vision-4.0-CURTAIN, where the system generates a complete 100% fingerprint of the panel. Inspection results are displayed instantly on the HMI and automatically stored for later use and analysis.

This is crucial for panel manufacturing, as it ensures consistent quality and helps detect defects at the earliest possible stage. By securing both process reliability and end-product quality, manufacturers can reduce waste, optimize efficiency, and guarantee customer satisfaction.