Edge-Vision-4.0-CURTAIN est un système d'inspection haute résolution qui assure un contrôle qualité fiable sur les lignes de production industrielles. Logé dans de robustes cadres CURTAIN en acier, il est conçu pour des performances durables dans les environnements de traitement en continu et par lots.

Le système capture et analyse des images détaillées des produits et des matériaux, permettant une détection et une classification rapides et précises des défauts de surface. Sa conception fermée bloque les interférences lumineuses externes, fournissant ainsi des résultats d'inspection constants et précis, même dans des conditions difficiles.

Avec son imagerie haute résolution, ses configurations adaptables et son fonctionnement robuste, Edge-Vision-4.0-CURTAIN est une solution puissante pour les fabricants visant à améliorer la précision, l'efficacité et la stabilité des processus.

Découvrez toutes nos technologiesChoosing the right lighting technique can improve defect detection, reduce false alarms, and ensure your inspection system delivers consistent, reliable results. The Edge-Vision-4.0-Curtain supports multiple lighting techniques, allowing you to optimize inspection results for a wide variety of applications:

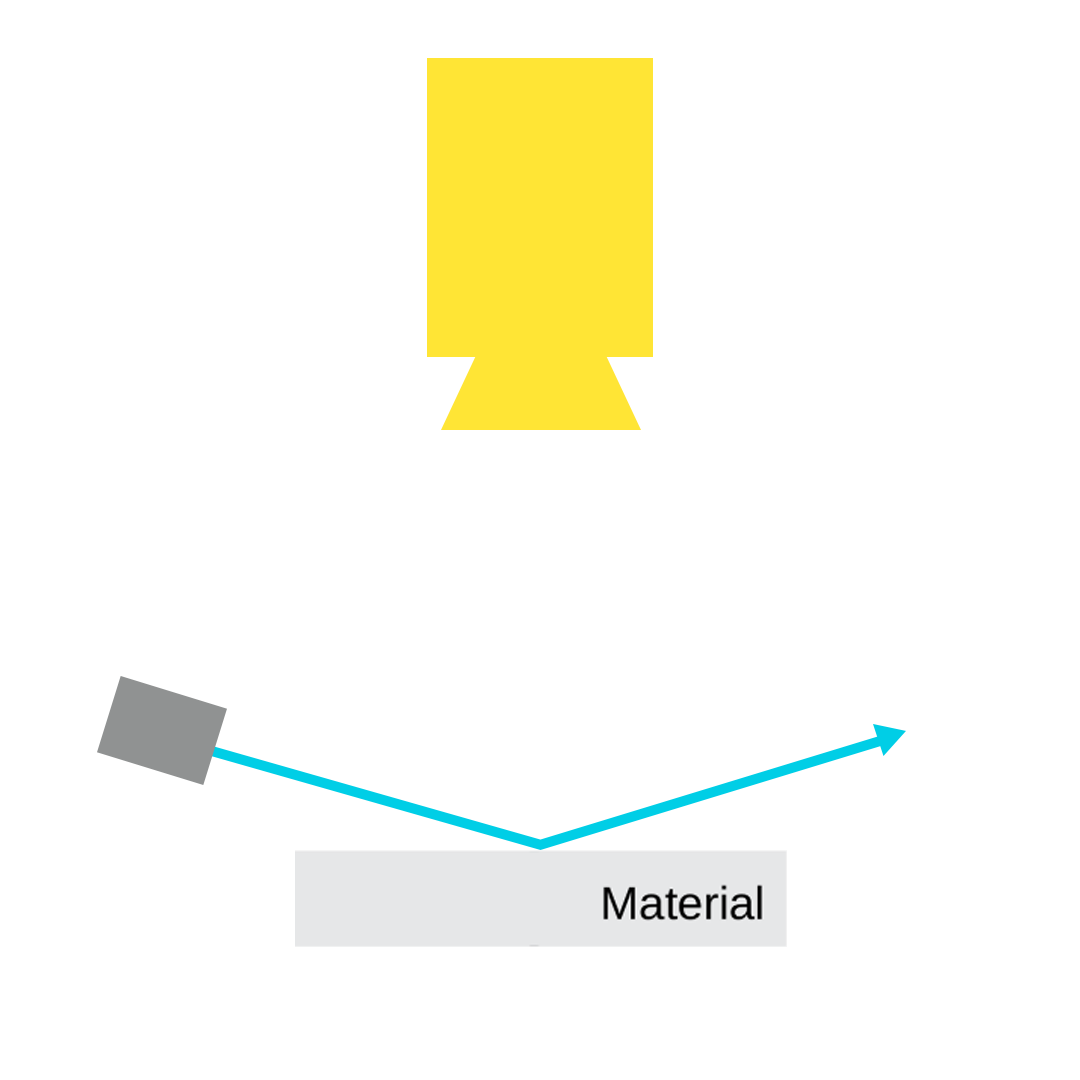

Bright-field lighting illuminates the object directly from above or the front, creating strong contrast on surface features and textures. It’s ideal for detecting surface defects, scratches or dirt on reflective or opaque materials.

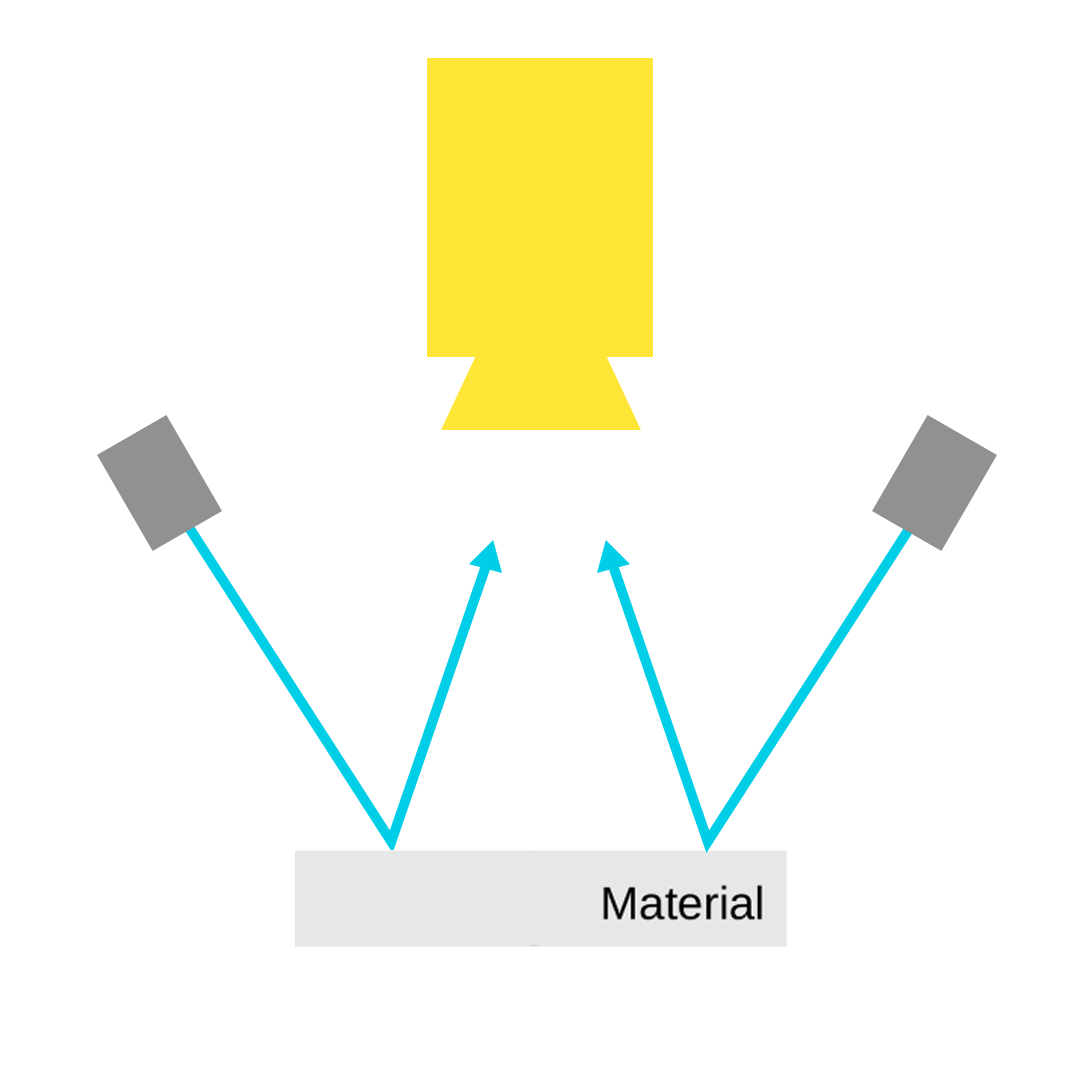

Dark-field lighting uses angled or side illumination, causing defects like scratches or bumps to scatter light differently than smooth surfaces. This highlights edges and surface irregularities with high contrast against a dark background, perfect for subtle surface inspection.

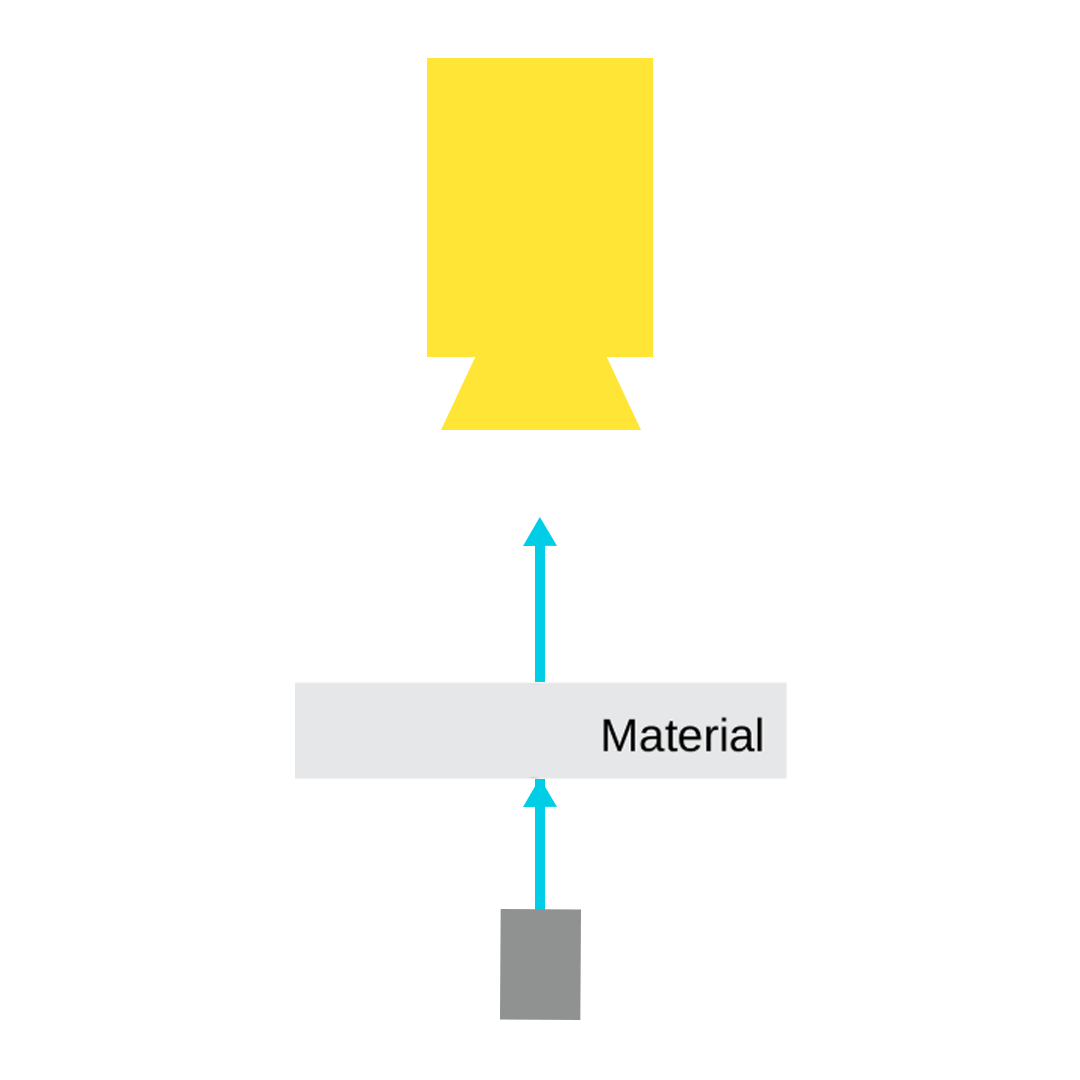

Transmission lighting illuminates the object from behind, allowing light to pass through transparent or semi-transparent materials. This method excels in inspecting holes, cracks, or inclusions in thin films, glass, plastics, or packaging materials.

The software environment for Edge-Vision-4.0 is called Connectivity 3.0. It provides a fully integrated quality control solution by combining different measurement tools within the same system. The software offers:

During production, each panel passes through the Edge-Vision-4.0-CURTAIN, where the system generates a complete 100% fingerprint of the panel. Inspection results are displayed instantly on the HMI and automatically stored for later use and analysis.

This is crucial for panel manufacturing, as it ensures consistent quality and helps detect defects at the earliest possible stage. By securing both process reliability and end-product quality, manufacturers can reduce waste, optimize efficiency, and guarantee customer satisfaction.