Nonwovens are fabric-like material made from staple fiber (short) and long fibers (continuous long), bonded together by chemical, mechanical, heat or solvent treatment. Nonwovens are fabrics, such as felt, which are neither woven nor knitted. To further increase strength, some nonwoven materials are densified or reinforced by a backing. In recent years, nonwovens have become an alternative to polyurethane foam.

The M-Ray based measuring systems of Hammer-IMS can be easily placed at different sites in a nonwoven production line. Our technology provides accurate and reliable measurements, enabling manufacturers to optimize their production processes and improve product quality while reducing waste.

Depending on your needs and application we can:

M-Ray technology plays a crucial role at two key stages of the production process:

Our L-Ray laser-based sensors are seamlessly integrated into the final step of the production process, enabling a complete analysis of the material’s thickness profile. This integration ensures precise measurement and quality control.

The Edge-Vision-4.0 system is integral to optimizing nonwovens production by detecting foreign objects, defects and anomalies at critical stages:

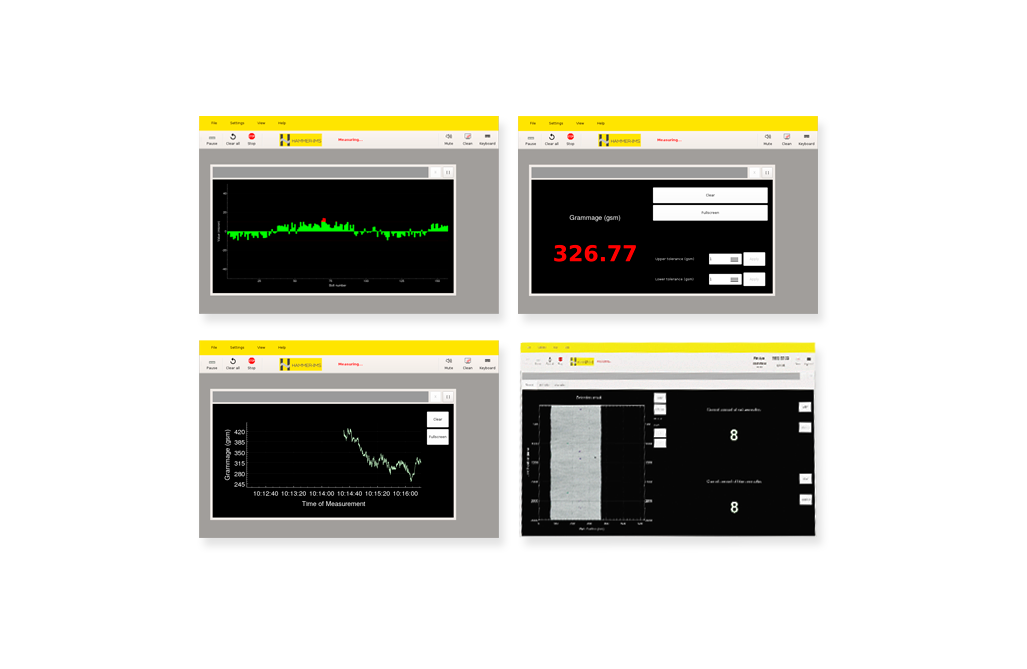

Together with the Autins Group we introduced a novel real-time evaluation of high-loft nonwovens uniformity using our patented in-line measurement technology. Autins Group, a leader in thermal and acoustic materials for the automotive industry, utilizes this technology with a modified uniformity index algorithm for precise quality control.

The integration of our technology has led to:

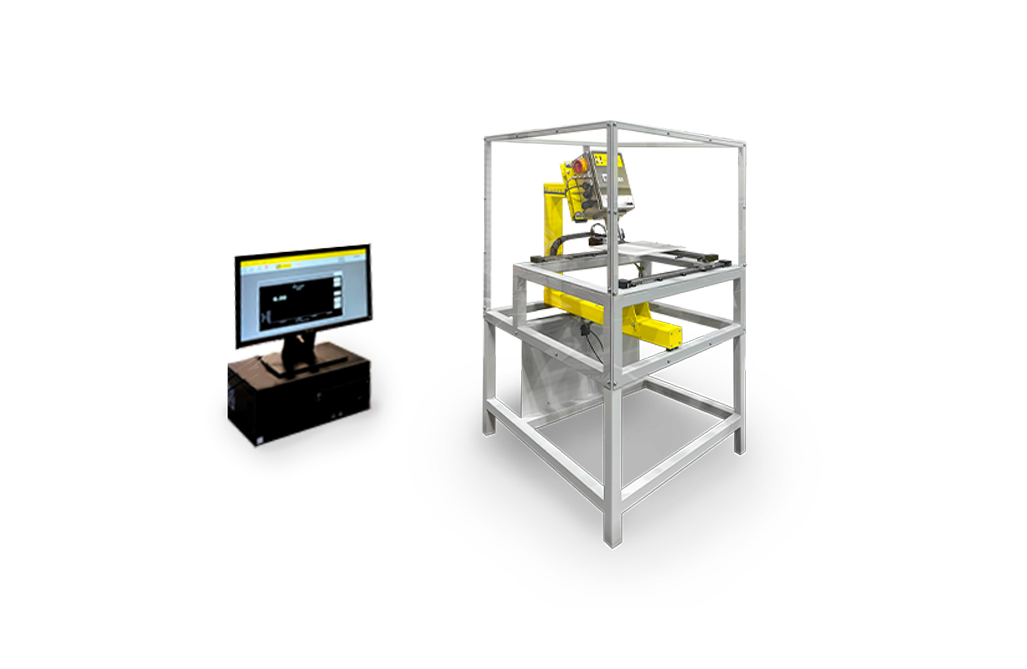

Surface inspection solution for detection of anomalies and defects

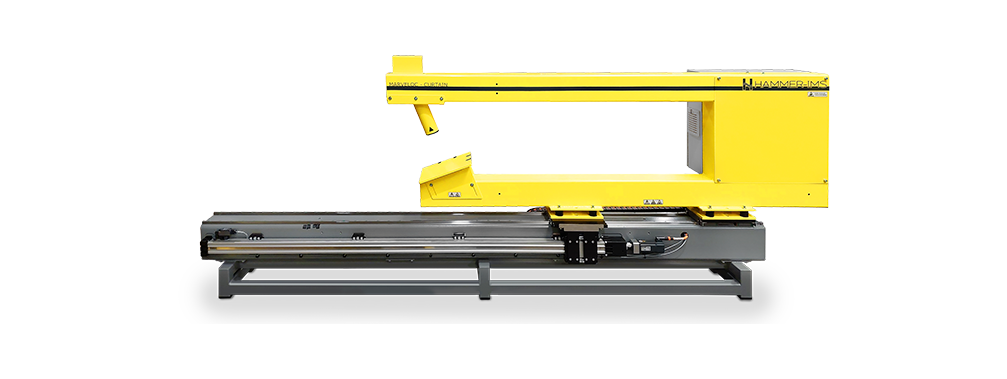

Machine for basis-weight measurement of flat materials

For OEM projects on basis-weight measuring by machine builders and sensor integrators

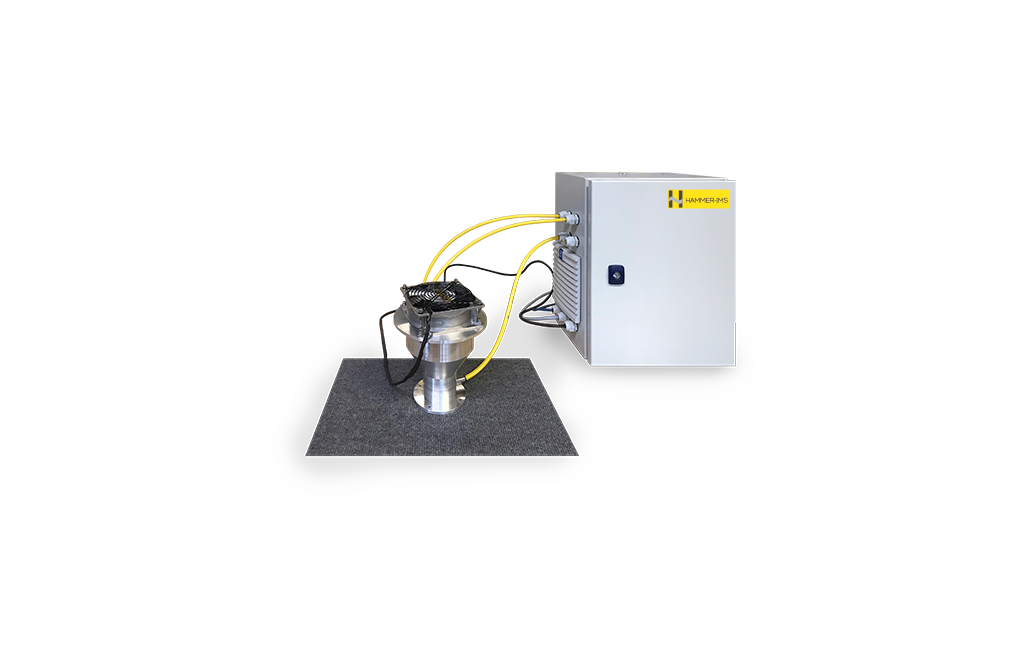

Device for air permeability measurement

Industrial software to connect to PLC's and various information sources

Lab devices, custom or off-the-shelf