Bilateral international agreement signed for coating grammage improvement in finishing lines for woven, tufted and needle-punched carpets and artificial grass.

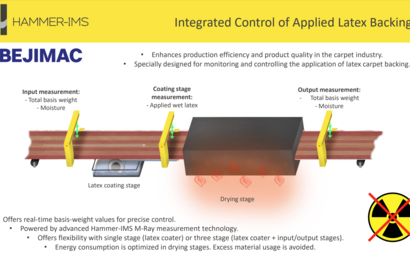

Vandewiele's daughter company Bejimac, specialist in textile finishing machines, established a structural collaboration with Hammer-IMS on quality control of latex coating. This agreement fits in the shared vision of Vandewiele, Bejimac and Hammer-IMS to digitalize the finishing lines for carpets in which accurate, adaptive measurement plays an essential role. Hammer-IMS dedicatedly integrates its non-nuclear technology for measuring coating grammage into Vandewiele-Bejimac finishing lines. Thanks to the real-time measurement and automatic system adaptation of these smart systems, carpet manufacturers maintain highest product quality while reducing the usage and scrap of expensive latex material. The collaboration agreement stipulates that Vandewiele sells and distributes its Hammer-IMS enabled finishing lines. This resellership covers the entire world, except EU, the United Kingdom, Norway and Switzerland.

Hammer-IMS installed an inline multi-sensor quality control system at Toiltech in France. Toiltech is specialized in manufacturing technical and industrial textiles. The project has been set up in collaboration with Erhardt+Leimer France, which represents Hammer-IMS in France.

Of course ... we are always moving with our new technology. But this time we are moving our HQ offices!

As of January 2022, Max Bertram joined Hammer-IMS as sales & business developer. It looks like Max thinks internationally and has experienced different cultures. Here is a brief Q&A to get to know Max a little bit better.

In the coming Fall and Winter months, Hammer-IMS will exhibit and/or participate in four events across Europe: Hofer Vliesstofftage in Hof (D), International Textile Coating & Lamination Congress in Ghent (B), K-Messe in Düsseldorf, and Global Insulation Conference & Exhibition in Estoril (P). Hammer-IMS will show a number of quality control solutions integrating plenty of innovations that provide instant feedback to manage and optimize your in-line production.

After INDEX in Geneva last November, Hammer-IMS resumed its exhibition tour across Germany in Winter & Spring 2022. Many people came and visited us to watch one of our non-nuclear inline thickness and basis weight measuring systems in action! For example, the sleek and slim C-frame based system proves to be ideal for quality control of foils and films as well as coatings, paper, fabrics, textiles and nonwovens.

A few months ago Joost Poelmans joined the Hammer-IMS team as R&D engineer. Say hello to Joost who studied engineering and collaborates on pushing the non-nuclear M-Ray weight and thickness measuring technology. He also introduces intelligent machine vision to further increase the quality control experience for plastic, textile and nonwoven manufacturers.

With many international system installations taking place, we want to point out that the design, delivery and installation process of your order is in good hands. Your purchase with Hammer-IMS is a smart move, not only while we are working to deliver your shiny yellow machine on time but also when the machine will be running at your facility in your production line of choice.

Our disruptive M-Ray technology is pure electronic by nature. This means that our non-nuclear measuring solutions are harmless for people and the environment. Completely safe for operators...

Every now and then, we give the word to one of our colleagues at Hammer-IMS. Today, Nele Reynders, Senior R&D Engineer, comments on the latest in measuring machine construction and measurement system integration.

Hammer-IMS kindly invites you to the upcoming Belgian event (co-organized by Hammer-IMS) where Technical and Product Manager Tom Redant will speak. The event includes short presentations related to innovative measuring techniques for coatings and a visit of the Hammer-IMS facilities.

Our new CURTAIN integrates a next-generation up to 4.5 meter mechanical frame equipped with multiple sensors based on our clean M-Ray based measurement technology. The solution is developed to perform 24/7 quality control on inline production of plastic films, nonwovens, fabrics, etc. The new Marveloc-CURTAIN solution entails product improvements covering proprietary mechanical frame, M-Ray sensors, and Connectivity software.