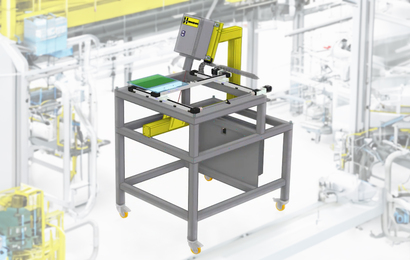

Discover the accuracy and precision of Hammer-IMS' 2D Scanner Demo Machine and its exceptional performance at various industry fairs. Visitors at ITMA Milan 2023 were able to experience firsthand the cutting-edge technology that has revolutionized quality control processes across multiple sectors. The revolutionary 2D-scanner is designed for unparalleled 100% inspection and measurement of basis-weights.

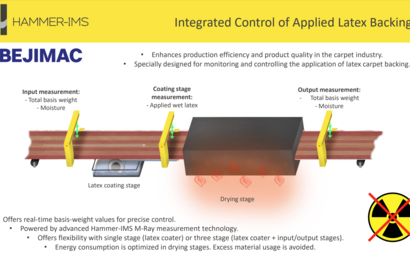

Bilateral international agreement signed for coating grammage improvement in finishing lines for woven, tufted and needle-punched carpets and artificial grass.

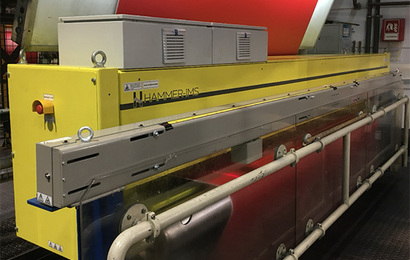

Vandewiele's daughter company Bejimac, specialist in textile finishing machines, established a structural collaboration with Hammer-IMS on quality control of latex coating. This agreement fits in the shared vision of Vandewiele, Bejimac and Hammer-IMS to digitalize the finishing lines for carpets in which accurate, adaptive measurement plays an essential role. Hammer-IMS dedicatedly integrates its non-nuclear technology for measuring coating grammage into Vandewiele-Bejimac finishing lines. Thanks to the real-time measurement and automatic system adaptation of these smart systems, carpet manufacturers maintain highest product quality while reducing the usage and scrap of expensive latex material. The collaboration agreement stipulates that Vandewiele sells and distributes its Hammer-IMS enabled finishing lines. This resellership covers the entire world, except EU, the United Kingdom, Norway and Switzerland.

The two-head M-Ray measuring system of Hammer-IMS ensures continuous grammage monitoring. In line with its sustainable corporate policy, Vetex is moving away from a radioactive source to a more sustainable technology. This installation is the result of a constructive collaboration between Le Clair & Meert, Vetex and Hammer-IMS.

We happily returned from the international INDEX Nonwovens expo in Geneva, Switzerland. After exhibiting in China last June, we demonstrated our sustainable measuring and machine vision solutions. Visitors watched various demos that nicely illustrate our one-stop-shop for safeguarding qualitative manufacturing. It was great to see some of you again in person and discuss your specific quality control applications

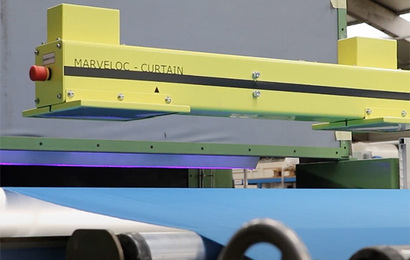

Watch our latest dual scanning system, which serves as an inline project for PMC felts at Heimbach Group (Olten, Switzerland). The automated M-Ray based system for grammage quality control eliminates radioactive sources at what the customer calls the pre-needle loom. We collaborated with Vansichen Linear Technology to fit a nearly 9 meters long steel linear module into a very limited inclined space envelope.

A few months ago Joost Poelmans joined the Hammer-IMS team as R&D engineer. Say hello to Joost who studied engineering and collaborates on pushing the non-nuclear M-Ray weight and thickness measuring technology. He also introduces intelligent machine vision to further increase the quality control experience for plastic, textile and nonwoven manufacturers.

For the first time, Hammer-IMS exhibits on the ITMA ASIA expo in Shanghai, China. This milestone event is China's most important textile event. "We are here to further extend our geographical reach and explore the huge Chinese market," says Tom Redant, CTO of Hammer-IMS. "We were able to scale geographically thanks to our non-nuclear M-Ray based systems for thickness and grammage measurement. Just recently, Hammer-IMS was awarded the VOKA Limburg export prize in Belgium. “We were able to scale geographically thanks to our non-nuclear M-Ray based systems for thickness and grammage measurement."

Known for the world's most advanced fabric technologies, Low & Bonar creates versatile materials in smart combinations to deliver performance. Since May 2020 part of German Freudenberg Performance Materials, Low & Bonar Hückelhoven is a pioneer in the technical textiles group. "The first purchased installation within the Low & Bonar has been running now for more than 10 months here in Hückelhoven, Germany," says Plant Manager Henk Hoekstra.

Due to the covid-19 pandemic, most international expos of 2020 are canceled or postponed. Therefore, we are setting up a new lineup of events for 2021 to be able to meet you in person and discuss your specific QC applications.

Started in January this year, Dirk Irle joined Hammer-IMS as a seasoned sales and business developer in the DACH region, Eastern Europe and Scandinavia. He has over 30 years experience in sales, marketing and technical support positions for a range of solution providers in measurement and engineering. Dirk has an engineering degree in computer science.

DILO - a leading German producer of fully-integrated nonwoven production lines - will showcase a system of Hammer-IMS on ITMA 2019.

Hello, I am Robin Michiels, your sales contact person for Hammer-IMS. You have probably heard about our M-Ray radar technology. It is a clean alternative for nuclear and radioactive measurement systems in production lines. Our M-Ray solutions measure the basis-weight or thickness of all kinds of flat materials – like nonwovens, fabrics, paper, plastics sheets or films.