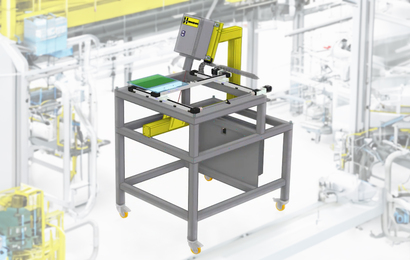

Entdecken Sie die Genauigkeit und Präzision der 2D-Scanner-Demomaschine von Hammer-IMS und ihre außergewöhnliche Leistung auf verschiedenen Fachmessen. Die Besucher der ITMA Milan 2023 konnten hautnah die bahnbrechende Technologie erleben, die die Qualitätskontrollprozesse in verschiedenen Sektoren revolutioniert hat. Der revolutionäre 2D-Scanner ist für eine unvergleichliche 100%-Inspektion und -Messung von Flächengewichten konzipiert.

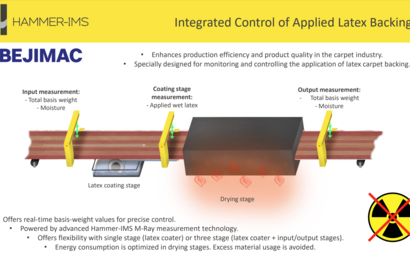

Bilaterales internationales Abkommen zur Verbesserung des Beschichtungsgewichts in Veredelungslinien für gewebte, getuftete und nadelgestanzte Teppiche sowie Kunstrasen unterzeichnet.

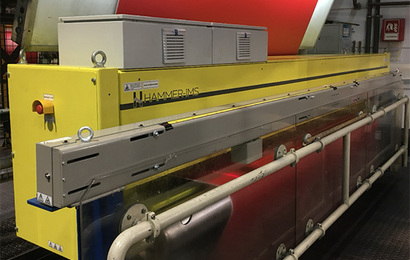

Die Tochtergesellschaft von Vandewiele, Bejimac, Spezialist für Textilveredelungsmaschinen, hat eine strukturelle Zusammenarbeit mit Hammer-IMS zur Qualitätskontrolle von Latexbeschichtungen etabliert. Dieses Abkommen passt in die gemeinsame Vision von Vandewiele, Bejimac und Hammer-IMS, die Veredelungslinien für Teppiche zu digitalisieren, wobei präzise, adaptive Messungen eine wesentliche Rolle spielen. Hammer-IMS integriert gezielt seine nicht-nukleare Technologie zur Messung des Beschichtungsgewichts in die Veredelungslinien von Vandewiele-Bejimac. Dank der Echtzeitmessung und automatischen Systemanpassung dieser intelligenten Systeme können Teppichhersteller die höchste Produktqualität beibehalten und gleichzeitig den Verbrauch und Abfall von teurem Latexmaterial reduzieren. Die Kooperationsvereinbarung sieht vor, dass Vandewiele seine Veredelungslinien, die mit Hammer-IMS-Technologie ausgestattet sind, vertreibt und verkauft. Diese Vertriebspartnerschaft umfasst die gesamte Welt, mit Ausnahme der EU, des Vereinigten Königreichs, Norwegens und der Schweiz.

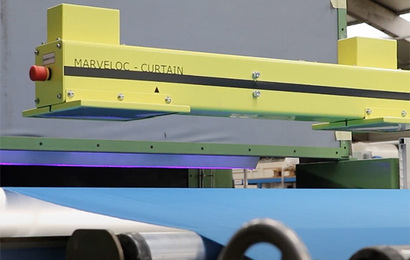

Das Zwei-Kopf-M-Ray-Messsystem von Hammer-IMS sorgt für eine kontinuierliche Grammaturüberwachung. Im Einklang mit seiner nachhaltigen Unternehmenspolitik bewegt sich Vetex von einer radioaktiven Quelle hin zu einer nachhaltigeren Technologie. Diese Installation ist das Ergebnis einer konstruktiven Zusammenarbeit zwischen Le Clair & Meert, Vetex und Hammer-IMS.

Wir sind glücklich von der internationalen INDEX Vliesstoffmesse in Genf, Schweiz, zurückgekehrt. Nach unserer Ausstellung in China im letzten Juni haben wir unsere nachhaltigen Mess- und Maschinenvisionslösungen präsentiert. Die Besucher konnten verschiedene Demos verfolgen, die unser One-Stop-Shop für die Sicherstellung qualitativ hochwertiger Fertigung anschaulich illustrieren. Es war großartig, einige von Ihnen wieder persönlich zu sehen und Ihre spezifischen Anwendungen zur Qualitätskontrolle zu besprechen.

Sehen Sie sich unser neuestes Dual-Scansystem an, das als Inline-Projekt für PMC-Filze bei der Heimbach Gruppe (Olten, Schweiz) dient. Das automatisierte, auf M-Ray basierende System zur Qualitätskontrolle der Grammatur eliminiert radioaktive Quellen an dem, was der Kunde als Pre-Nadelwebstuhl bezeichnet. Wir haben mit Vansichen Linear Technology zusammengearbeitet, um ein fast 9 Meter langes Stahl-Linearmodul in einen sehr begrenzten, geneigten Raum einzupassen.

Vor einigen Monaten trat Joost Poelmans als R&D-Ingenieur dem Hammer-IMS-Team bei. Begrüßen Sie Joost, der Ingenieurwissenschaften studiert hat und an der Förderung der nicht-nuklearen M-Ray-Messung von Gewicht und Dicke mitarbeitet. Er führt auch intelligente Maschinenvision ein, um das Qualitätskontrollerlebnis für Hersteller von Kunststoffen, Textilien und Vliesstoffen weiter zu verbessern.

Erstmals präsentiert sich Hammer-IMS auf der ITMA ASIA-Messe in Shanghai, China. Diese wegweisende Veranstaltung ist die wichtigste Textilmessen in China. "Wir sind hier, um unsere geografische Reichweite weiter auszubauen und den riesigen chinesischen Markt zu erkunden", sagt Tom Redant, CTO von Hammer-IMS. "Wir konnten geografisch expandieren dank unserer nicht-nuklearen M-Ray-basierten Systeme zur Dicken- und Grammaturmessung. Vor kurzem wurde Hammer-IMS mit dem VOKA Limburg Exportpreis in Belgien ausgezeichnet. „Wir konnten geografisch expandieren dank unserer nicht-nuklearen M-Ray-basierten Systeme zur Dicken- und Grammaturmessung."

Low & Bonar, bekannt für die weltweit fortschrittlichsten Gewebetechnologien, entwickelt vielseitige Materialien in intelligenten Kombinationen, um Leistung zu bieten. Seit Mai 2020 Teil der deutschen Freudenberg Performance Materials, ist Low & Bonar Hückelhoven ein Pionier in der Gruppe der technischen Textilien. „Die erste gekaufte Installation innerhalb von Low & Bonar läuft jetzt seit mehr als 10 Monaten hier in Hückelhoven, Deutschland“, sagt Werksleiter Henk Hoekstra.

Due to the covid-19 pandemic, most international expos of 2020 are canceled or postponed. Therefore, we are setting up a new lineup of events for 2021 to be able to meet you in person and discuss your specific QC applications.

Hallo, ich bin Robin Michiels, Ihr Ansprechpartner für den Vertrieb bei Hammer-IMS. Sie haben wahrscheinlich von unserer M-Ray-Radartechnologie gehört. Sie ist eine saubere Alternative zu nuklearen und radioaktiven Messsystemen in Produktionslinien. Unsere M-Ray-Lösungen messen das Flächengewicht oder die Dicke aller Arten von flachen Materialien – wie Vliesstoffe, Stoffe, Papier, Kunststoffplatten oder -folien.

Hallo, mein Name ist Bram Iliaens. Kürzlich habe ich als Produkt- und Entwicklungsingenieur bei Hammer-IMS angefangen.

Wir freuen uns, in der belgischen Trends-Zeitschrift vorgestellt zu werden. Der Artikel hebt unsere Radartechnologie hervor, die eine saubere Alternative zu nuklearen und radioaktiven Messsystemen darstellt. Unsere M-Ray-Messlösungen messen das Flächengewicht von Vliesstoffen, Stoffen usw. und die Dicke von Kunststoffplatten und -folien. Die Lösungen unterstützen sogar die Inline-Messung des Beschichtungsgewichts von undurchsichtigen Materialien, bei denen Röntgensysteme möglicherweise versagen.

Klicken Sie hier, um den Hammer-IMS-Artikel in der Trends-Zeitschrift zu lesen (Niederländisch):