Polymerschäume bestehen aus einer festen und einer Gasphase, die zusammen ein Schaumgebilde formen. Eine gleichmäßige Zellstruktur wird durch synthetische Schaumextrusion erreicht, bei der Gas entweder injiziert wird (physikalisches Schäumen) oder durch Hitze entsteht (chemisches Schäumen) und gründlich im Polymerschmelze dispergiert werden muss. Stickstoff, Kohlendioxid, Pentan oder Butan werden beim physikalischen Schäumen verwendet. Chemisches Schäumen nutzt chemische Substanzen, die sich beim Erhitzen zersetzen.

Synthetische Schäume werden in Blöcken und Rollen hergestellt. Blockschäume werden geschnitten und aufgeschnitten, während dünnere Schäume auf Rollen produziert werden. Die beliebtesten Materialien, die in Schäumen verwendet werden, sind PU (Polyurethan), PP (Polypropylen) und PE (Polyethylen). Weitere Materialien umfassen EVA, PE, NBR, PS, PVC, Silikon und EPDM.

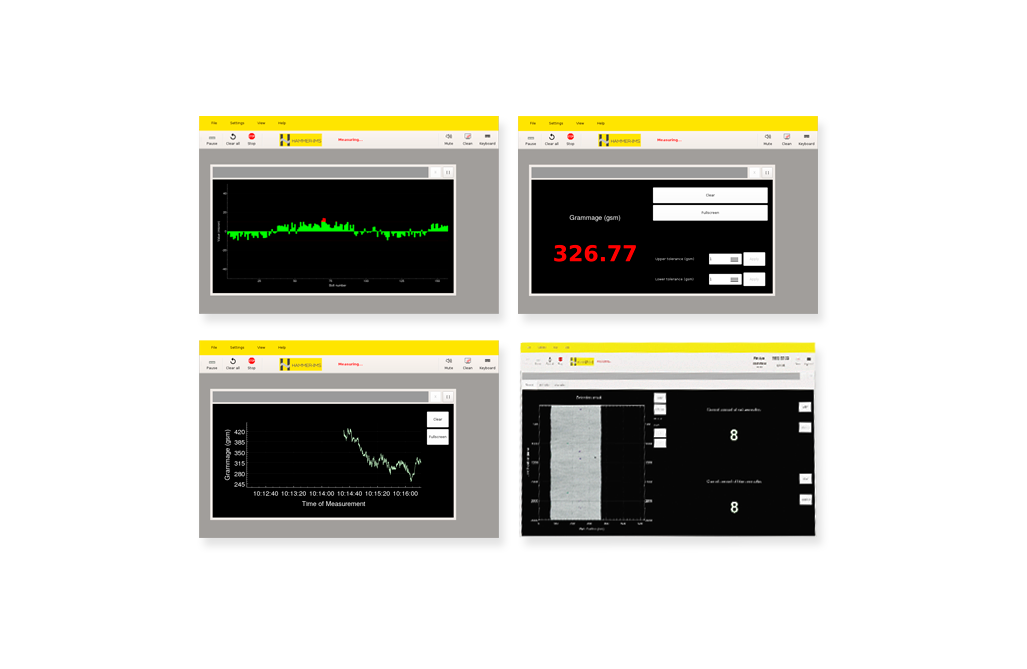

Hammer-IMS bietet Lösungen sowohl für die Dicken- als auch für die Dichtemessung von Schäumen. Die Dichteinformationen werden aus dem gemessenen Flächengewicht und der gemessenen Dicke berechnet.

Die geringe Dichte von Schäumen macht sie zu hervorragenden Wärmedämmstoffen und Schwimmhilfen, und ihre Leichtigkeit und Komprimierbarkeit macht sie ideal als Verpackungsmaterialien und Füllstoffe. Die zufällige Geometrie dieser Schäume sorgt zudem für eine gute Energieabsorption. Neuere Herstellungstechniken haben Geometrien ermöglicht, die hervorragende Festigkeit und Steifigkeit im Verhältnis zum Gewicht bieten. Thermoplastische Schäume finden neue Anwendungen in verschiedenen Branchen, darunter die Automobil-, Sportbekleidungs-, Medizin-, Verpackungs- und Möbelindustrie.

Schäume, die auf Rollen geliefert werden, werden meist mit einer Produktionslinie hergestellt, die aus zylindrischen Extrusions- und Schäumungsstufen besteht. Im Rahmen des Inline-Produktionsprozesses wird die dünne zylindrische Schicht aufgeschlitzt und horizontal gezogen.

Erdölbasierte starre Schaumplatten werden aus verschiedenen Materialien hergestellt, darunter PIR (Polyisocyanurat – z. B. Polyiso), XPS (extrudiertes Polystyrol – z. B. Styropor), EPS (expandiertes Polystyrol) oder Styropor. Neben diesen Lösungen gibt es auch Platten auf Basis von Mineralwolle (z. B. Isover). All diese Dämmplatten tragen zu einer leistungsstarken Gebäudekonstruktion und -renovierung bei und können mit den auf M-Ray basierenden Lösungen von Hammer-IMS gemessen werden.

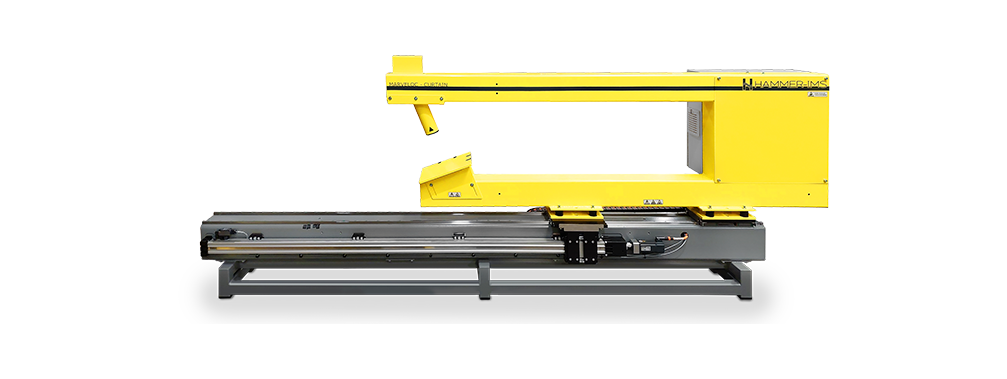

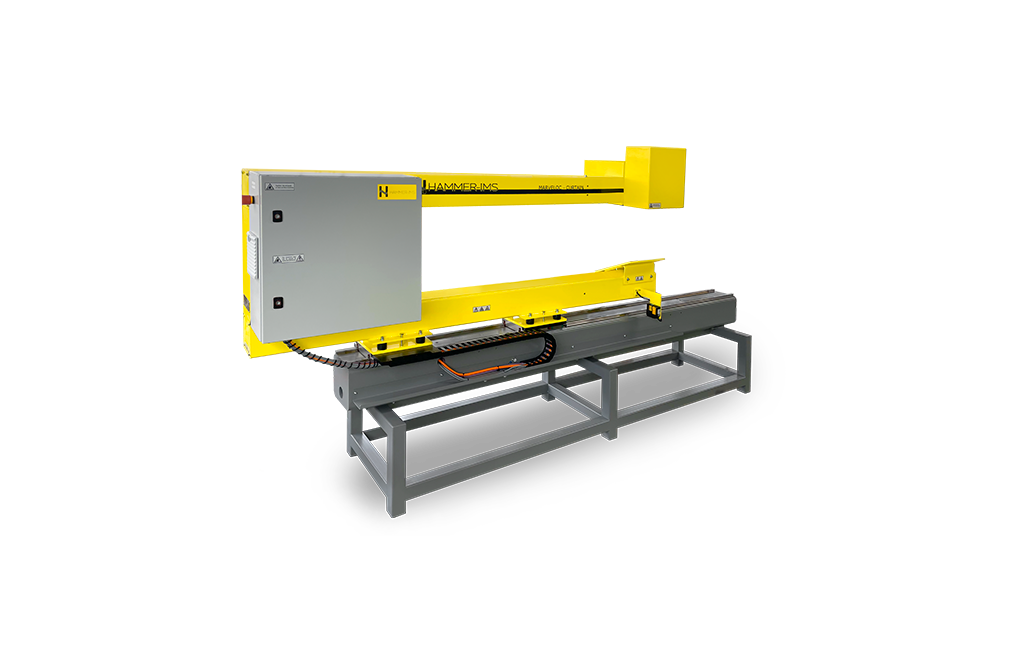

Bevor der Schaum auf Rollen gesammelt wird, können sich Schaumhersteller für die Integration einer Marveloc-CURTAIN-Lösung entscheiden, um die Schaumdicke und/oder -dichte zu messen. Ein oder mehrere feste oder verfahrbare Sensoren gewährleisten eine maximale Abdeckung in Querrichtung. Bei der Erkennung lokaler Abweichungen werden die Maschinenbediener informiert, damit sie geeignete Maßnahmen ergreifen können. Der Marveloc-CURTAIN eignet sich gleichermaßen für den Einsatz in Flachschau-Extrusionsanlagen.

Die auf M-Ray basierenden Messlösungen von Hammer-IMS bieten niedrigere Gesamtkosten (TCO) im Vergleich zu herkömmlichen nuklearen und radioaktiven Messtechnologien. Das sind gute Nachrichten für Schaumstoffhersteller, die ihre Produktionslinien mit schnellerer und präziserer Qualitätskontrolle ausstatten möchten.

Die Messung des Flächengewichts und/oder der Dicke von Schäumen führt zu einer gleichmäßigen Produktionsqualität. Ebenso wichtig ist, dass eine präzise Inline-Messung es den Herstellern ermöglicht, Schäume gemäß den Spezifikationen zu produzieren, anstatt konstant Schaum zu produzieren, der etwas zu dick ist. Auf diese Weise sparen Schaumhersteller, die rund um die Uhr produzieren, enorme Mengen an Rohmaterial ein.

Surface inspection solution for detection of anomalies and defects

Machine for basis-weight measurement of flat materials

Machine for thickness measurement of flat materials

Machine for thickness measurement of flat materials

For OEM projects on basis-weight measuring by machine builders and sensor integrators

Machine for thickness measurement of flat materials

Industrial software to connect to PLC's and various information sources

Lab devices, custom or off-the-shelf