Watch the Hammer-IMS company video to dive into the world of sustainable industrial quality control systems.

Spartanburg, SC - Press release for September 15, 2023 -

Hammer-IMS, an innovative force in the field of contactless measuring and vision systems for industrial applications, celebrates a momentous occasion - the official grand opening of its offices in Spartanburg County, SC. The event, which took place on Wednesday September 13th marked a significant milestone in the company's journey towards providing cutting-edge solutions to revolutionize the manufacturing industry. Hammer-IMS, originally a Belgian tech-start-up company, founded in 2016, has now officially crossed the Atlantic Ocean and is currently in search for people to start-up its American team.

We wanted to take a moment to celebrate our long-time partner and supplier, Beckhoff, by sharing a crate of our belgian brewed beer!

Hammer-IMS is thrilled to announce its new operations in Spartanburg County, USA, as it expands its global presence. The company has established itself at the Spark Center SC's soft-landing space, marking a significant milestone in its growth and international expansion.

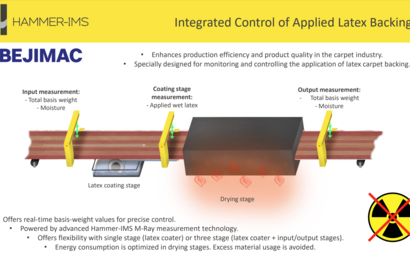

Bilateral international agreement signed for coating grammage improvement in finishing lines for woven, tufted and needle-punched carpets and artificial grass.

Vandewiele's daughter company Bejimac, specialist in textile finishing machines, established a structural collaboration with Hammer-IMS on quality control of latex coating. This agreement fits in the shared vision of Vandewiele, Bejimac and Hammer-IMS to digitalize the finishing lines for carpets in which accurate, adaptive measurement plays an essential role. Hammer-IMS dedicatedly integrates its non-nuclear technology for measuring coating grammage into Vandewiele-Bejimac finishing lines. Thanks to the real-time measurement and automatic system adaptation of these smart systems, carpet manufacturers maintain highest product quality while reducing the usage and scrap of expensive latex material. The collaboration agreement stipulates that Vandewiele sells and distributes its Hammer-IMS enabled finishing lines. This resellership covers the entire world, except EU, the United Kingdom, Norway and Switzerland.

Fruitful collaboration with metalworking company in Hasselt results in robust and accurate mechanical structures with sleek yellow finishing for a worldwide export market

Of course ... we are always moving with our new technology. But this time we are moving our HQ offices!

As of January 2022, Max Bertram joined Hammer-IMS as sales & business developer. It looks like Max thinks internationally and has experienced different cultures. Here is a brief Q&A to get to know Max a little bit better.

In the coming Fall and Winter months, Hammer-IMS will exhibit and/or participate in four events across Europe: Hofer Vliesstofftage in Hof (D), International Textile Coating & Lamination Congress in Ghent (B), K-Messe in Düsseldorf, and Global Insulation Conference & Exhibition in Estoril (P). Hammer-IMS will show a number of quality control solutions integrating plenty of innovations that provide instant feedback to manage and optimize your in-line production.

Hammer-IMS is looking for a #studentjob #sql #azure for improving and migrating our Microsoft Access Database to an Azure platform. A maximum of 40 full-time days spread over 4 months.

Does this sound like you? Contact us at tom.redant@hammer-ims.com

The two-head M-Ray measuring system of Hammer-IMS ensures continuous grammage monitoring. In line with its sustainable corporate policy, Vetex is moving away from a radioactive source to a more sustainable technology. This installation is the result of a constructive collaboration between Le Clair & Meert, Vetex and Hammer-IMS.