Sehen Sie sich das Hammer-IMS Unternehmensvideo an, um in die Welt der nachhaltigen industriellen Qualitätskontrollsysteme einzutauchen.

Spartanburg, SC - Pressemitteilung vom 15. September 2023 -

Hammer-IMS, eine innovative Kraft im Bereich der kontaktlosen Mess- und Visionstechnologien für industrielle Anwendungen, feiert einen bedeutenden Anlass - die offizielle Eröffnung seiner Büros im Spartanburg County, SC. Die Veranstaltung, die am Mittwoch, dem 13. September, stattfand, markierte einen wichtigen Meilenstein auf dem Weg des Unternehmens, modernste Lösungen zur Revolutionierung der Fertigungsindustrie anzubieten. Hammer-IMS, ursprünglich ein belgisches Tech-Start-up, das 2016 gegründet wurde, hat nun offiziell den Atlantik überquert und sucht derzeit nach Mitarbeitern, um sein amerikanisches Team aufzubauen.

Wir wollten uns einen Moment Zeit nehmen, um unseren langjährigen Partner und Lieferanten, Beckhoff, zu feiern, indem wir eine Kiste unseres belgisch gebrauten Bieres teilen!

Hammer-IMS freut sich, seine neuen Aktivitäten im Spartanburg County, USA, bekannt zu geben, da das Unternehmen seine globale Präsenz erweitert. Das Unternehmen hat sich im Soft-Landing-Bereich des Spark Centers SC niedergelassen, was einen bedeutenden Meilenstein in seinem Wachstum und seiner internationalen Expansion darstellt.

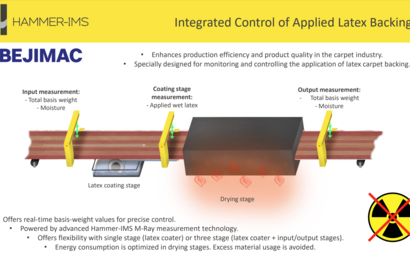

Bilaterales internationales Abkommen zur Verbesserung des Beschichtungsgewichts in Veredelungslinien für gewebte, getuftete und nadelgestanzte Teppiche sowie Kunstrasen unterzeichnet.

Die Tochtergesellschaft von Vandewiele, Bejimac, Spezialist für Textilveredelungsmaschinen, hat eine strukturelle Zusammenarbeit mit Hammer-IMS zur Qualitätskontrolle von Latexbeschichtungen etabliert. Dieses Abkommen passt in die gemeinsame Vision von Vandewiele, Bejimac und Hammer-IMS, die Veredelungslinien für Teppiche zu digitalisieren, wobei präzise, adaptive Messungen eine wesentliche Rolle spielen. Hammer-IMS integriert gezielt seine nicht-nukleare Technologie zur Messung des Beschichtungsgewichts in die Veredelungslinien von Vandewiele-Bejimac. Dank der Echtzeitmessung und automatischen Systemanpassung dieser intelligenten Systeme können Teppichhersteller die höchste Produktqualität beibehalten und gleichzeitig den Verbrauch und Abfall von teurem Latexmaterial reduzieren. Die Kooperationsvereinbarung sieht vor, dass Vandewiele seine Veredelungslinien, die mit Hammer-IMS-Technologie ausgestattet sind, vertreibt und verkauft. Diese Vertriebspartnerschaft umfasst die gesamte Welt, mit Ausnahme der EU, des Vereinigten Königreichs, Norwegens und der Schweiz.

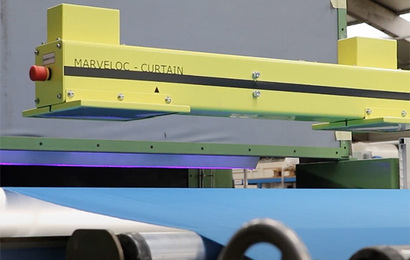

Erfolgreiche Zusammenarbeit mit einem Metallbauunternehmen in Hasselt führt zu robusten und präzisen mechanischen Strukturen mit einer eleganten gelben Lackierung für den weltweiten Exportmarkt

Natürlich ... wir sind immer mit unserer neuen Technologie in Bewegung. Aber dieses Mal ziehen wir unsere HQ-Büros um!

Seit Januar 2022 ist Max Bertram als Sales & Business Developer zu Hammer-IMS gestoßen. Es scheint, als denke Max international und habe verschiedene Kulturen erlebt. Hier ist ein kurzes Q&A, um Max ein wenig besser kennenzulernen.

In den kommenden Herbst- und Wintermonaten wird Hammer-IMS auf vier Veranstaltungen in ganz Europa ausstellen und/oder teilnehmen: Hofer Vliesstofftage in Hof (D), International Textile Coating & Lamination Congress in Gent (B), K-Messe in Düsseldorf und Global Insulation Conference & Exhibition in Estoril (P). Hammer-IMS wird eine Reihe von Lösungen zur Qualitätskontrolle präsentieren, die zahlreiche Innovationen integrieren und sofortige Rückmeldungen bieten, um Ihre Inline-Produktion zu steuern und zu optimieren.

Das Zwei-Kopf-M-Ray-Messsystem von Hammer-IMS sorgt für eine kontinuierliche Grammaturüberwachung. Im Einklang mit seiner nachhaltigen Unternehmenspolitik bewegt sich Vetex von einer radioaktiven Quelle hin zu einer nachhaltigeren Technologie. Diese Installation ist das Ergebnis einer konstruktiven Zusammenarbeit zwischen Le Clair & Meert, Vetex und Hammer-IMS.

Das Zertifikat 'Hammer-IMS Internship Fellow' für Hochschulabsolventen setzt einen neuen Akzent auf dem flämischen Arbeitsmarkt. Als Hammer-IMS 2016 auf dem Corda-Technologiekampus in Hasselt ansässig wurde, hatten die Gründer Noël Deferm und Tom Redant keine Ahnung, dass sie fünf Jahre später jeden Monat eine große gelbe Maschine in alle Ecken der Welt versenden würden. „Unsere leuchtend gelbe Farbe ist unser Markenzeichen“, sagt Hammer-IMS. "In den letzten Jahren haben wir gesehen, wie sich unser Unternehmen von der Entwicklung eines einzelnen technischen Bauteils zu vollwertigen Maschinen entwickelt hat. Große internationale Textil- und Kunststoffkonzerne betrachten unsere Produkte mit großem Interesse und wählen oft unsere Maschinen gegenüber denen etablierter deutscher Unternehmen. Unser Cocktail aus technologischer Leidenschaft und Marktverankerung ist entscheidend für den Markteintritt und die Steigerung unseres Anteils. Wir möchten dies an neue junge Fachkräfte weitergeben."