Sheet metal is formed by an industrial process into thin flat sheet material stored as large coils, mostly through rolling or extrusion. Many different metals can be made into sheet metal: aluminum, brass, copper, steel, tin, nickel, titanium, etc. Sheet metal is widely used in metalworking, as it can be cut and bent into a variety of shapes to serve many industries. Parts manufactured from sheet metal must maintain a uniform thickness for ideal results.

The L-Ray sensor technology of Hammer-IMS applies two opposing laser sensors to measure the differential thickness of sheet metal. The emitted laser spots of each L-Ray sensor must be properly aimed and aligned along the entire measurement span. Inline sheet metal manufacturers benefit from highly accurate and reliability L-Ray sensors, which correctly distinguish between good and scrap product. Metal in general exhibits sufficient reflectivity for laser-based thickness measurement. As a result, the operation of L-Ray sensors is material independent without requiring alloy-dependent calibration.

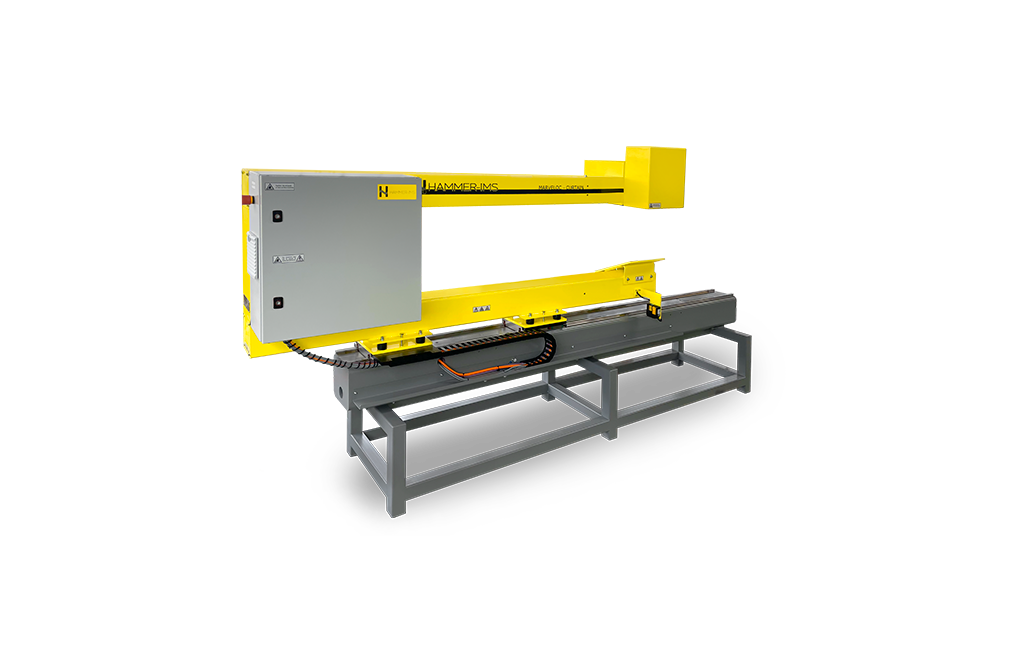

Machine for thickness measurement of flat materials

Machine for thickness measurement of flat materials

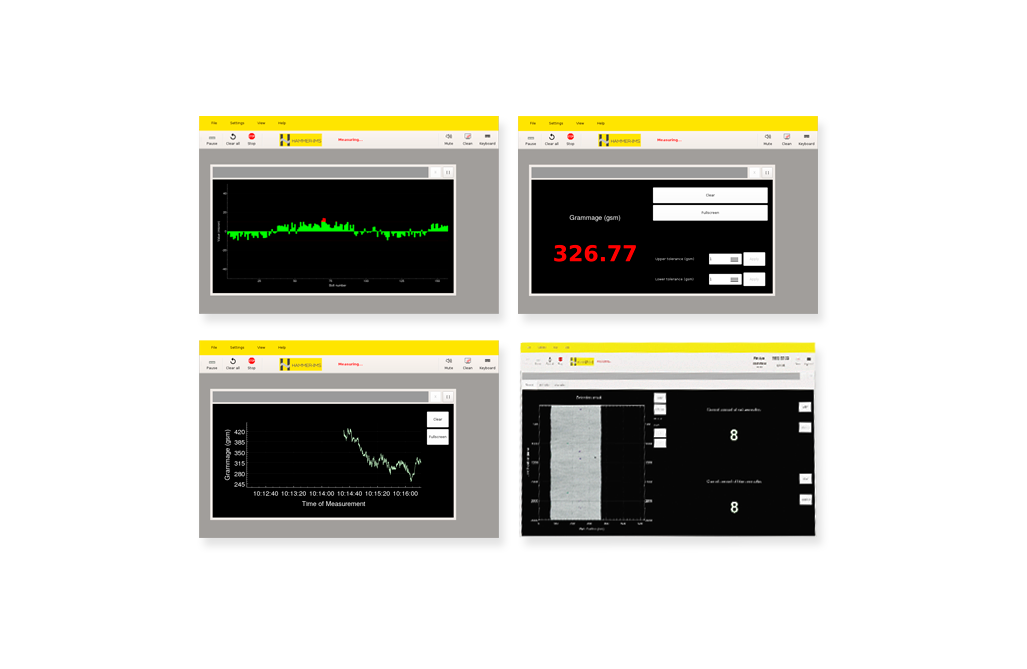

Industrial software to connect to PLC's and various information sources

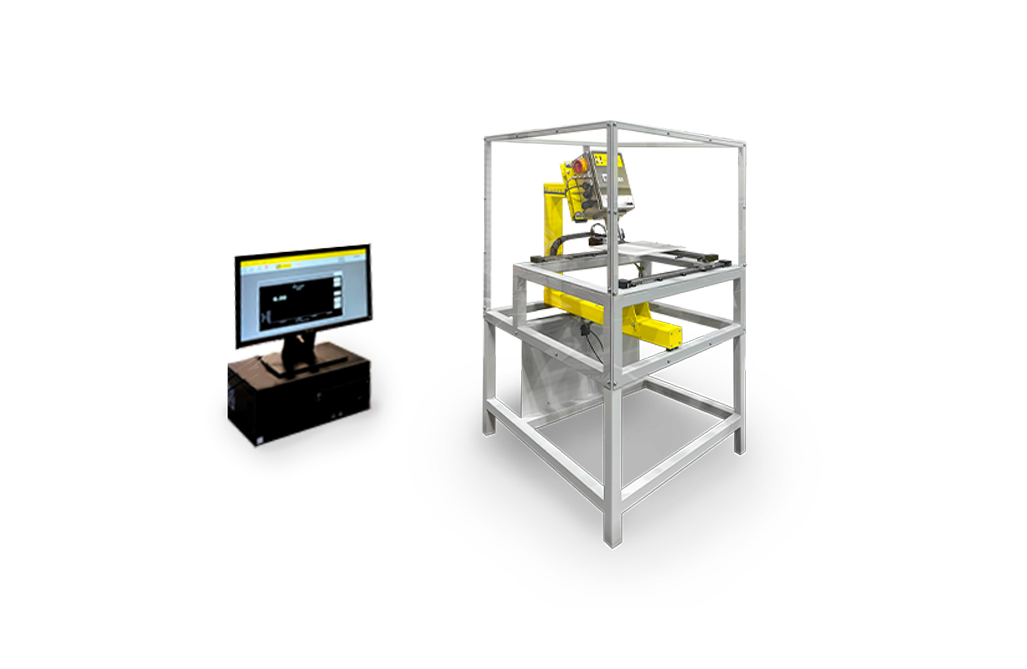

Lab devices, custom or off-the-shelf