The process of manufacturing paper or fabric based wall coverings typically involves coating, printing, and pre-pasting steps. A backing material, often paper, fabric, or nonwoven, is first coated with a ground color using colored vinyl (PVC) or a similar substance. After this, patterns are applied through surface, gravure, silk screen, or rotary printing. The process usually concludes with a wet coating step. Once dried, the finished product is ready for final inspection and quality control.

Het proces van het vervaardigen van wandbekledingen op basis van papier of stof omvat coaten, bedrukken en voorplakken. In veel gevallen is het achtermateriaal gecoat met een grondkleur met gekleurd vinyl (PVC) of een andere stof. Vervolgens kunnen patroonbedrukkingstechnieken worden toegepast met behulp van oppervlaktetechnieken, gravure, zeefdruk of rotatieve druk. De laatste stap omvat doorgaans een nat coatingproces. Na het drogen kan het basisgewicht van de afgewerkte wandbekledingen worden geverifieerd met behulp van een basisgewicht kwaliteitscontrolesysteem van Hammer-IMS, dat het materiaal in de transversale richting scant voor maximale materiaaldekking. Het systeem kan worden uitgerust met één of meer sensoren. Naast basisgewichtinspectie worden wandbekledingen onderworpen aan visuele kwaliteitscontrole.

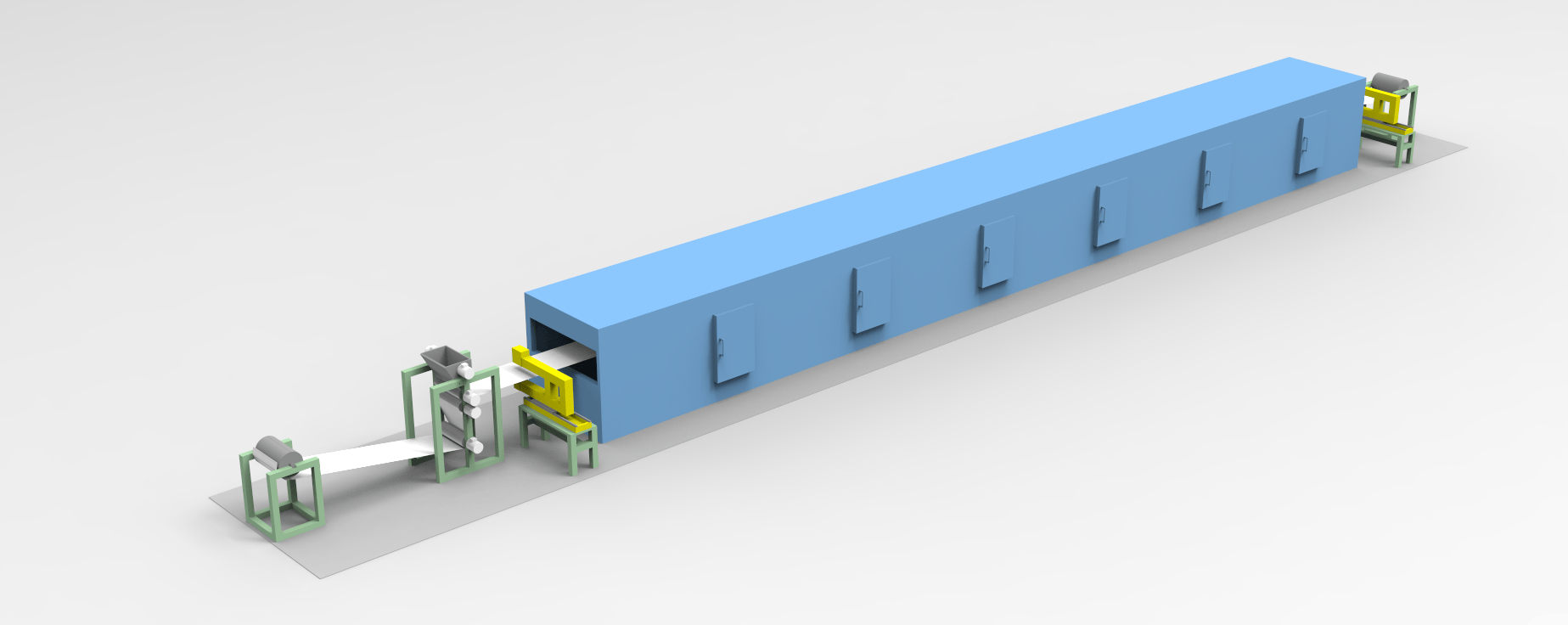

Visual appearance is just as critical as material performance in wall coverings. The Edge-Vision-4.0-CURTAIN system delivers inline optical inspection, detecting surface flaws that might go unnoticed by weight or thickness measurements alone.

Installed after printing or final coating, it checks for pattern alignment, print defects, color inconsistencies, or surface contamination. A second unit can be positioned at the final inspection stage to ensure that edge defects and aesthetic issues are identified before winding or packaging.

Key capabilities include:

Together with Grandeco Wallfashion Group, we’ve brought real-time weight monitoring to the production of decorative wallcoverings. By integrating our non-contact measurement technology, Grandeco can now track and control coating weight with high precision. This ensures their premium wallcoverings meet exact specifications every time.

The integration of our technology has led to: