The process of manufacturing paper or fabric based wall coverings typically involves coating, printing, and pre-pasting steps. A backing material, often paper, fabric, or nonwoven, is first coated with a ground color using colored vinyl (PVC) or a similar substance. After this, patterns are applied through surface, gravure, silk screen, or rotary printing. The process usually concludes with a wet coating step. Once dried, the finished product is ready for final inspection and quality control.

Le processus de fabrication des revêtements muraux à base de papier ou de tissu comprend le revêtement, l'impression et le préencollage. Dans de nombreux cas, le matériau de support est revêtu d'une couleur de fond à l'aide de vinyle coloré (PVC) ou d'une autre substance. Ensuite, des techniques d'impression de motifs peuvent être appliquées, telles que l'impression en surface, héliogravure, sérigraphie ou impression rotative. L'étape finale consiste généralement en une procédure de revêtement humide. Après séchage, le grammage des revêtements muraux finis peut être vérifié à l'aide d'un système de contrôle qualité du grammage Hammer-IMS, qui scanne le matériau dans la direction transversale pour une couverture maximale. Le système peut être équipé d'un ou plusieurs capteurs. En plus de l'inspection du grammage, les revêtements muraux font l'objet d'un contrôle qualité visuel.

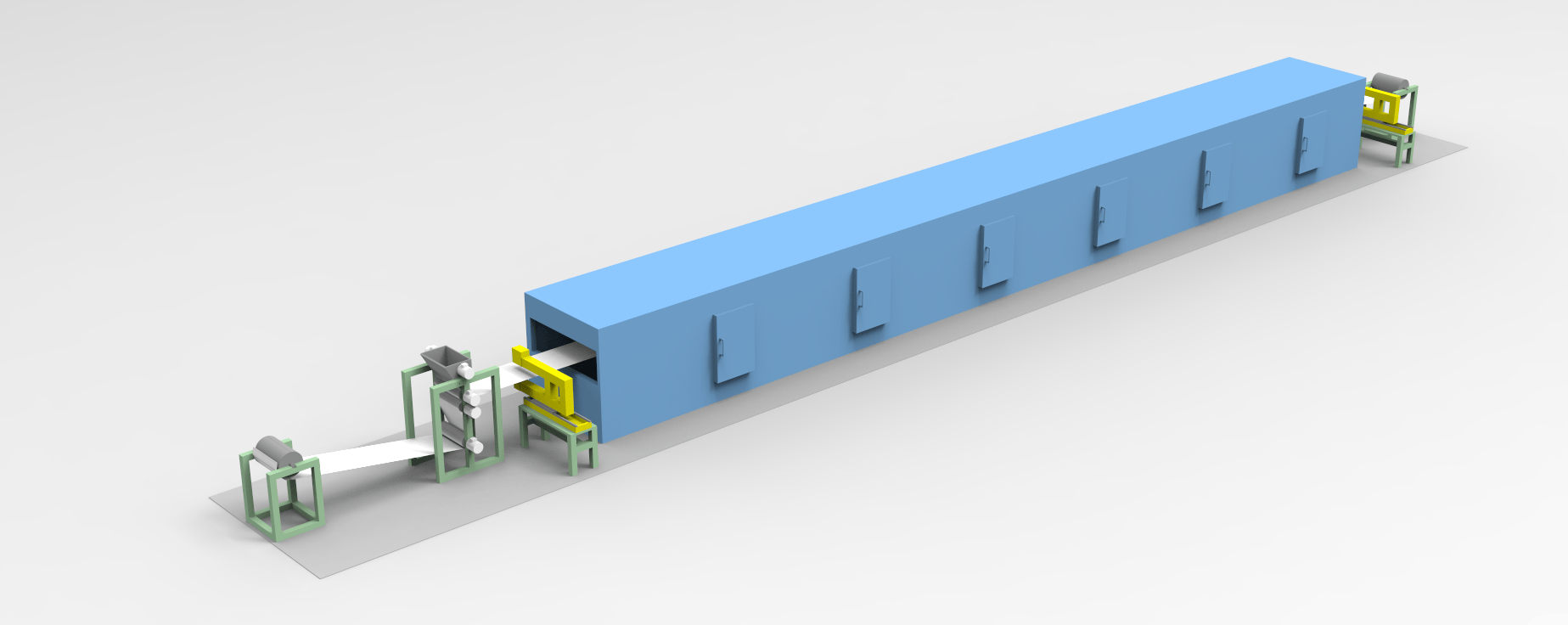

Visual appearance is just as critical as material performance in wall coverings. The Edge-Vision-4.0-CURTAIN system delivers inline optical inspection, detecting surface flaws that might go unnoticed by weight or thickness measurements alone.

Installed after printing or final coating, it checks for pattern alignment, print defects, color inconsistencies, or surface contamination. A second unit can be positioned at the final inspection stage to ensure that edge defects and aesthetic issues are identified before winding or packaging.

Key capabilities include:

Together with Grandeco Wallfashion Group, we’ve brought real-time weight monitoring to the production of decorative wallcoverings. By integrating our non-contact measurement technology, Grandeco can now track and control coating weight with high precision. This ensures their premium wallcoverings meet exact specifications every time.

The integration of our technology has led to: