The new 2021 Marveloc-CHARIOT (or shorter the Chariot!) is perfectly suited for new production lines or space-limited retrofits for true thickness measurement. The compact system efficiently measures thicknesses on high-precision mode (material thickness up to 25 mm) or extended-range mode (material thickness above 25 mm). A single measuring head moves across the entire product width instead of the complete frame. With the innovative measuring head and the latest evaluation technology, you can optimize your processes and ensure high production quality.

The Chariot platform is equipped by our Marveloc technology, more specifically with our C-Ray or L-Ray sensor. The C-Ray based Chariot machine measures the thickness of thin materials such as plastic films whereas the L-Ray machine version measures thicker insulation sheets, extruded sheets and foams. The Chariot contains a reference roll which is measured by an inductive sensor. Chariot's minimal-effort sensor integration and the moving sensor unit within the fixed machine frame, prove extremely valuable for inline thickness measurement that is cost and space efficient.

The Marveloc-CHARIOT is unique in its simplicity as it offers a single traveling sensor unit. Since only the sensor travels across the product, no additional space next to the production line is required for the Chariot frame to move in or out. Therefore, the Chariot is the ideal solution to retrofit existing plastic production lines. A small footprint and high mechanical rigidity characterize the Chariot, irrespective of product width. This means that it can be flexibly integrated into any new or existing production line.

Concretely, the Chariot accurately and affordably measures a multitude of materials: from thin films to thick multi-layered LVT sheets and PVC foams.

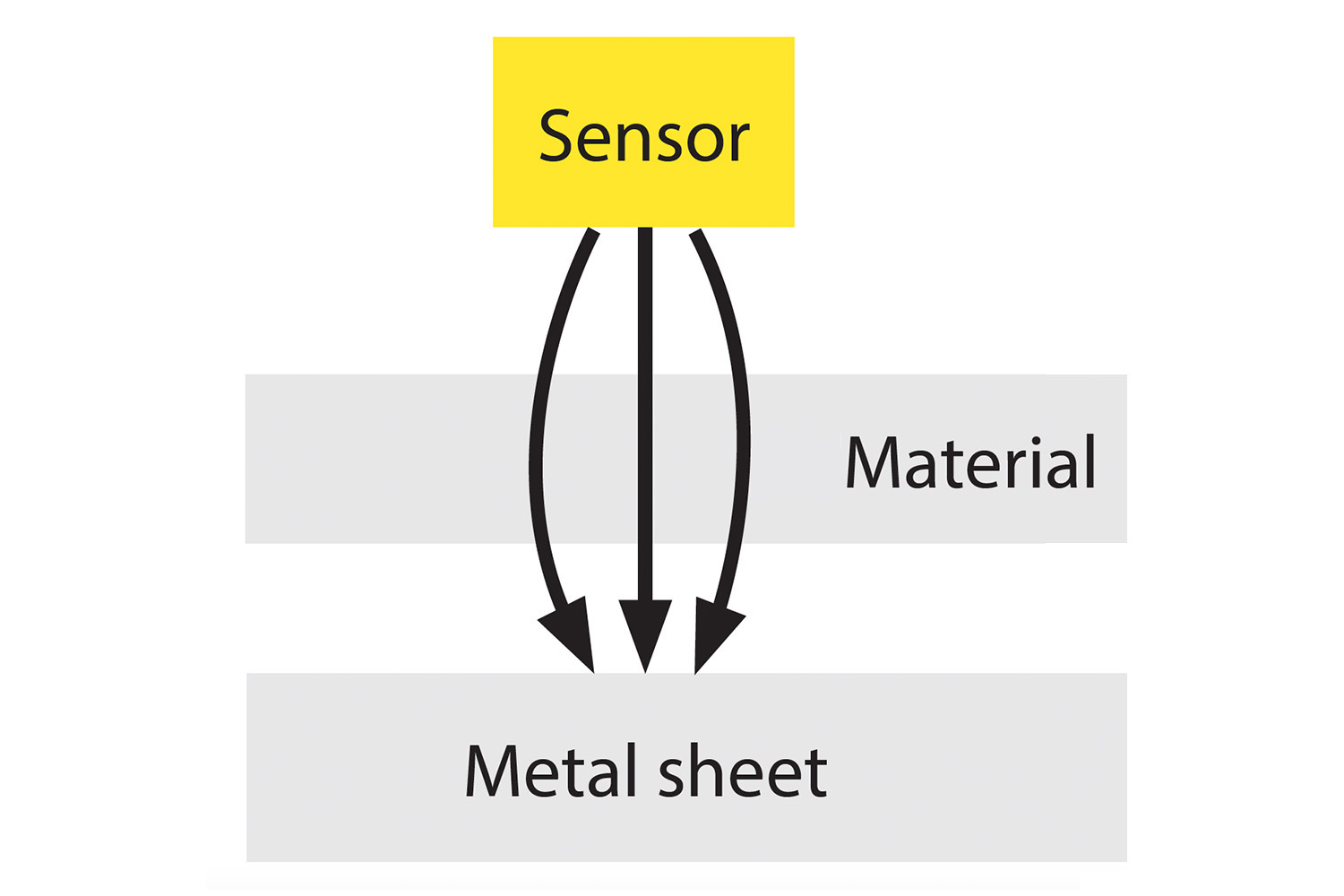

Our C-Ray technology combines robust capacitive technology with integrated variable-standoff compensation. Hammer-IMS develops its own internal capacitive solutions that are either optimized for small measurement spot, precise measurement performance, increased measurement gap, or a combination hereof.

The C-Ray based system variant measures thin materials such as plastic film applications with thicknesses between 20 micron up to 4 mm. The minimal-effort integration of the C-Ray technology into our Chariot scanners, makes this solution extremely valuable for thickness measurement in thin-film plastics extrusion lines. This innovative solution is cost-sensitive and typically come with limited space next to the extrusion line.

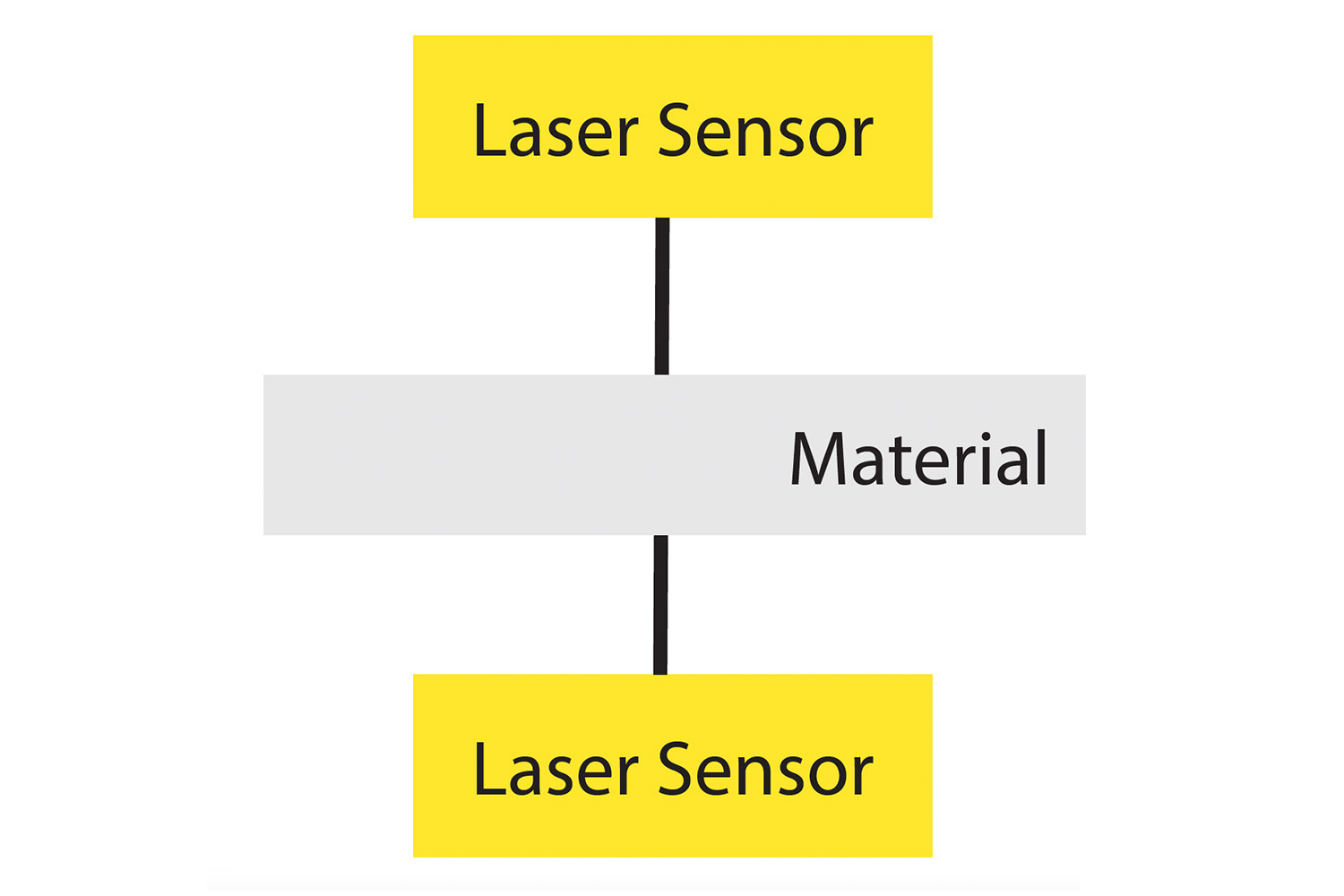

The Marveloc L-Ray technology is based on one or more laser triangulation sensors. In a typical setup, the L-Ray sensor technology of Hammer-IMS applies two opposing laser sensors to measure the thickness of sheets and films in a differential way (one laser on top, the other below).

The choice of the specific sensor will be matched with the customer application at hand: high-range versus high-precision, optimized for rough or shiny surface, etc. The L-Ray based Chariot measures the thickness of a range of flooring and construction materials up to 200 mm thick.

The Chariot's disruptive L-Ray or C-Ray technology represents a viable alternative for nuclear and radioactive measuring equipment currently used in the market. These innovative measuring technologies are gaining popularity among many international producers.

The Connectivity software controls the Chariot measurement solution in a single software environment. The software is easy to use, contains various industry-specific visualizations, and comes pre-installed on a rugged industrial PC or a desktop PC offering a widescreen experience. It offers a various number of both time-stamped and position-based visualizations. The Hammer-IMS software also supports closed-loop feedback control. It allows the production to be adjusted automatically to maintain high production quality and minimize material scrap.

The flexibility, versatility and limited space envelop of the affordable Chariot reduces the total cost of ownership (TCO) of inline measurements significantly. The measuring frame, the measuring principle and the software can be individually adapted to your process. An increasing number of manufacturers opt for C-Ray or L-Ray based Marveloc-CHARIOT systems of Hammer-IMS for thickness quality control of their production.