Mineralwolle, Steinwolle und Glaswolle sind die wichtigsten Dämmstoffe in Häusern und öffentlichen Gebäuden. Je dicker oder schwerer das Material, desto besser sind seine Dämmeigenschaften. Dämmstoffe lassen sich in organische und anorganische Dämmstoffe unterteilen. Im Allgemeinen sind organische Dämmstoffe, wie z. B. Styropor oder Polyurethan, extrem anfällig für Feuer. Anorganische Dämmstoffe, zu denen Mineralwolle und Glaswolle gehören, sind nicht brennbar. Die Dämmstoffe aus Mineralwolle, Steinwolle und Glaswolle enthalten zufällig verflochtene Fasermassen unterschiedlicher Länge, die durch ein Bindemittel zusammengehalten werden. Zu den Hauptprodukten gehören Dämmrollen mit niedriger Dichte, Platten mit mittlerer und hoher Dichte, lose Wolle zum Einblasen und Rohrisolierungen.

Allgemeine Vorteile unserer Qualitätsmesssysteme:

Marveloc Sensortechnologien

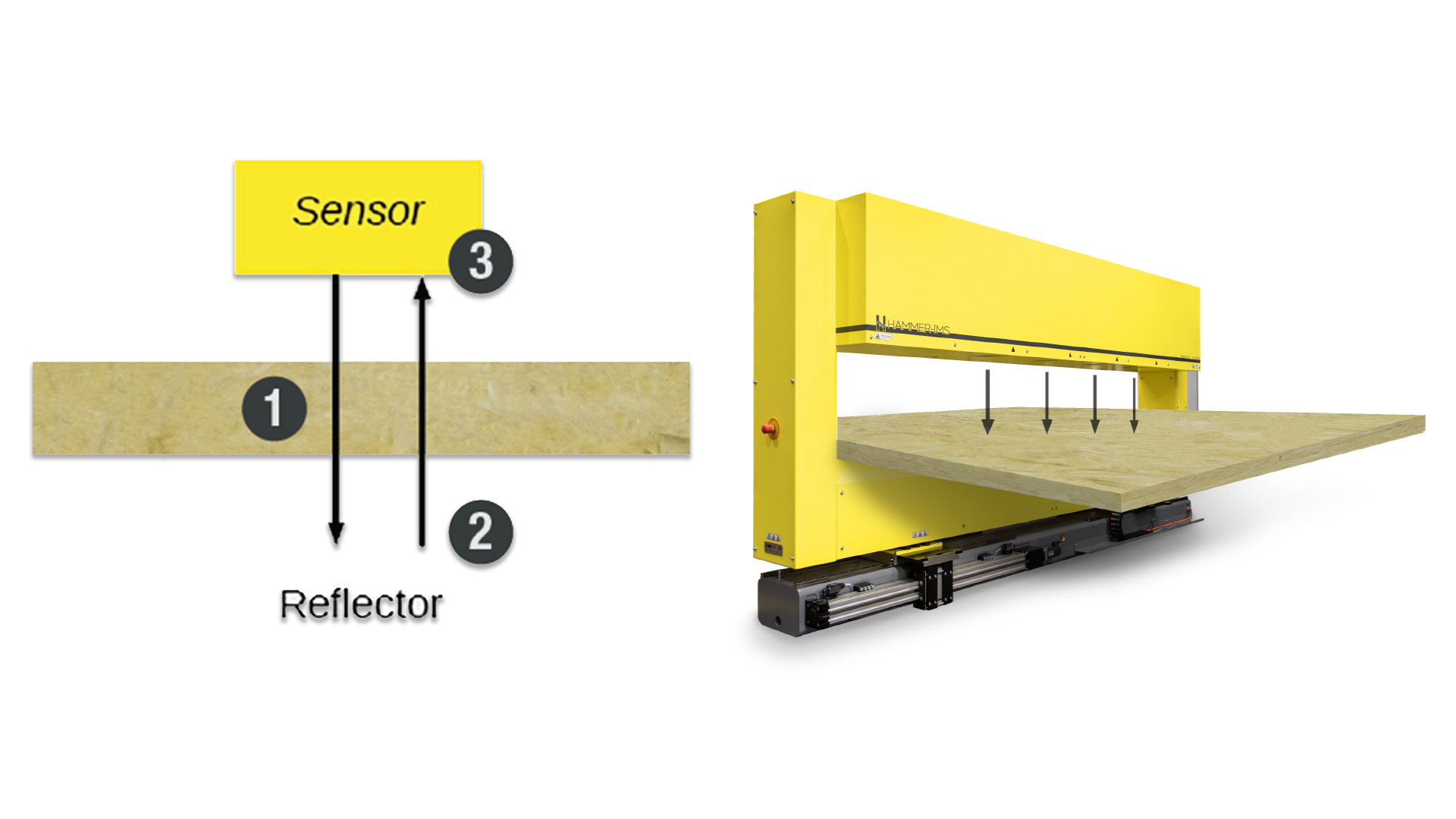

Das Konzept unserer M-Ray-Technologie zur Flächengewichtsmessung (Grammatur) ist einfach: Ein Sensor oben sendet eine Millimeterwelle aus. Diese Welle durchdringt das Material, das wir messen möchten. (1) Wenn sie den Boden erreicht, wird sie von einem Reflektor abgelenkt (2) und durchdringt das Material ein zweites Mal. Schließlich erreicht sie erneut den Sensor, wo wir sie erfassen und analysieren können. (3)

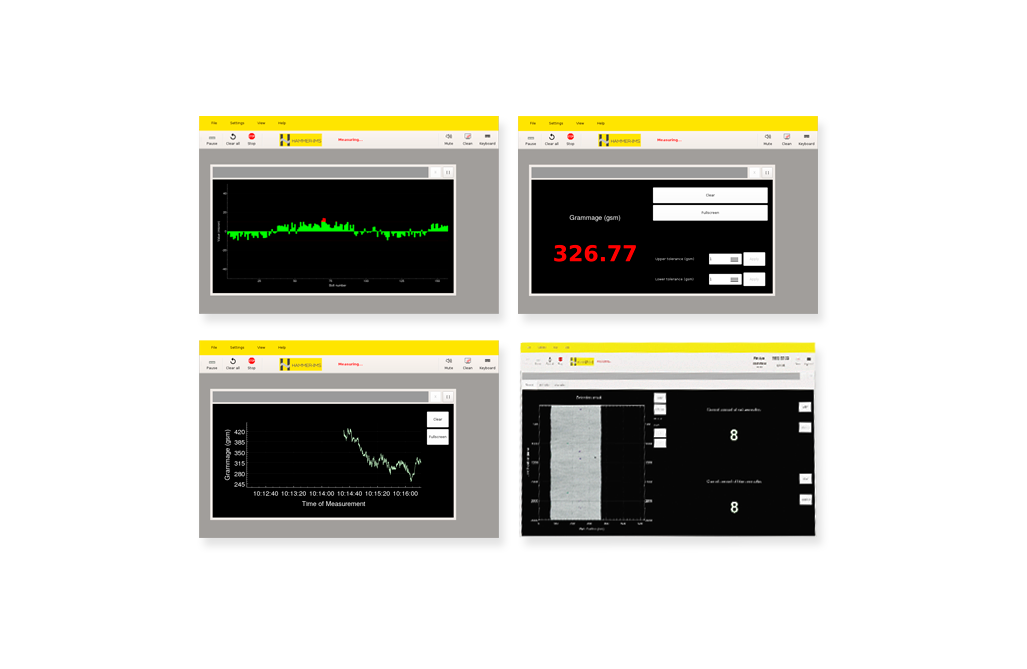

Echtzeit-Erkennung von Produktabweichungen

M-Ray-Sensoren erkennen Produktabweichungen in Ihrem Produktionsprozess mit der geringsten Verzögerung. 2D-Farbkarten zeigen grafisch die Bereiche mit der höchsten und niedrigsten Grammatur der produzierten Produkte. Mit einem Frequenzanalysewerkzeug können systematische und periodische Abweichungen in der Maschinenrichtung ermittelt werden, um diese Abweichungen besser zu kontrollieren.

The Edge-Vision-4.0 system with integrated FLIR thermal cameras is the ideal solution for detecting hotspots in insulation wool production. As the wool exits the curing oven or production line, the system continuously monitors the surface temperature in real time, identifying thermal anomalies such as uneven curing, binder buildup, or localized overheating. This non-contact, high-resolution inspection enables early detection of defects that could compromise fire safety or material integrity.

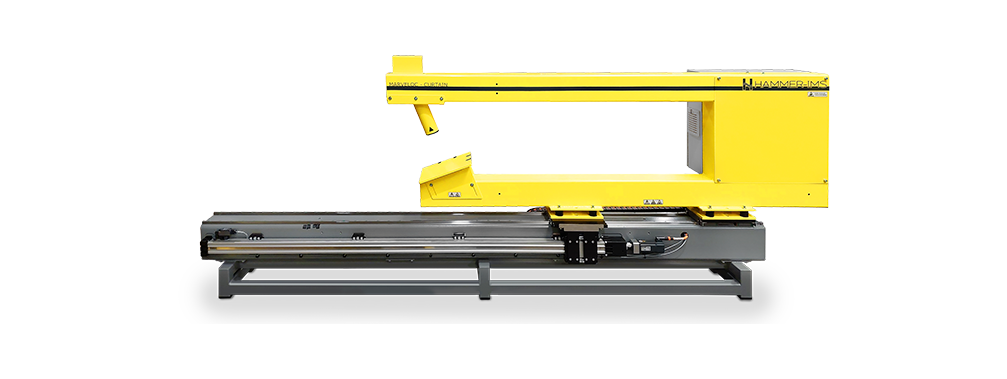

Multisensorische Messung für 100% Materialabdeckung

Unsere Qualitätskontrollsysteme mit mehreren Sensoren wurden entwickelt, um Gewicht und Dicke gleichzeitig zu messen. Der Einsatz mehrerer Sensoren ermöglicht eine Materialabdeckung von bis zu 100%. Durch die Maximierung der Abdeckung optimieren unsere Systeme die Effizienz und minimieren das Risiko von Defekten, was letztendlich die Gesamtqualität des Endprodukts verbessert.

Machine for basis-weight measurement of flat materials

For OEM projects on basis-weight measuring by machine builders and sensor integrators

Industrial software to connect to PLC's and various information sources

Lab devices, custom or off-the-shelf