Entdecken Sie die Genauigkeit und Präzision der 2D-Scanner-Demomaschine von Hammer-IMS und ihre außergewöhnliche Leistung auf verschiedenen Fachmessen. Die Besucher der ITMA Milan 2023 konnten hautnah die bahnbrechende Technologie erleben, die die Qualitätskontrollprozesse in verschiedenen Sektoren revolutioniert hat. Der revolutionäre 2D-Scanner ist für eine unvergleichliche 100%-Inspektion und -Messung von Flächengewichten konzipiert.

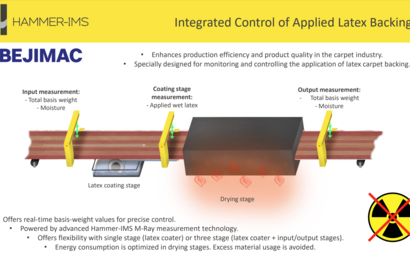

Bilaterales internationales Abkommen zur Verbesserung des Beschichtungsgewichts in Veredelungslinien für gewebte, getuftete und nadelgestanzte Teppiche sowie Kunstrasen unterzeichnet.

Die Tochtergesellschaft von Vandewiele, Bejimac, Spezialist für Textilveredelungsmaschinen, hat eine strukturelle Zusammenarbeit mit Hammer-IMS zur Qualitätskontrolle von Latexbeschichtungen etabliert. Dieses Abkommen passt in die gemeinsame Vision von Vandewiele, Bejimac und Hammer-IMS, die Veredelungslinien für Teppiche zu digitalisieren, wobei präzise, adaptive Messungen eine wesentliche Rolle spielen. Hammer-IMS integriert gezielt seine nicht-nukleare Technologie zur Messung des Beschichtungsgewichts in die Veredelungslinien von Vandewiele-Bejimac. Dank der Echtzeitmessung und automatischen Systemanpassung dieser intelligenten Systeme können Teppichhersteller die höchste Produktqualität beibehalten und gleichzeitig den Verbrauch und Abfall von teurem Latexmaterial reduzieren. Die Kooperationsvereinbarung sieht vor, dass Vandewiele seine Veredelungslinien, die mit Hammer-IMS-Technologie ausgestattet sind, vertreibt und verkauft. Diese Vertriebspartnerschaft umfasst die gesamte Welt, mit Ausnahme der EU, des Vereinigten Königreichs, Norwegens und der Schweiz.

Erfolgreiche Zusammenarbeit mit einem Metallbauunternehmen in Hasselt führt zu robusten und präzisen mechanischen Strukturen mit einer eleganten gelben Lackierung für den weltweiten Exportmarkt

Abriso-Jiffy ist ein Pionier in der umweltfreundlichen Produktion mit einem Inline-Qualitätskontrollsystem von Hammer-IMS.

Lesen Sie hier ihr Testimonial

Sehen Sie sich unser neuestes Dual-Scansystem an, das als Inline-Projekt für PMC-Filze bei der Heimbach Gruppe (Olten, Schweiz) dient. Das automatisierte, auf M-Ray basierende System zur Qualitätskontrolle der Grammatur eliminiert radioaktive Quellen an dem, was der Kunde als Pre-Nadelwebstuhl bezeichnet. Wir haben mit Vansichen Linear Technology zusammengearbeitet, um ein fast 9 Meter langes Stahl-Linearmodul in einen sehr begrenzten, geneigten Raum einzupassen.

ANL Plastics – ein international renommierter Hersteller von tiefgezogenen Kunststoffverpackungen – setzt nun in seinen Produktionsstätten in Wellen, Belgien, Anlagen von Hammer-IMS ein. Hammer-IMS, ein gemeinsames Start-up der KU Leuven Universität Belgien und der LRM Belgien, hat kürzlich sein Marveloc-CURTAIN-Messsystem an den Verpackungshersteller geliefert. Das System enthält vier M-Ray-Sensoren, die kontinuierlich die Kunststoffdicke an einer Produktionsmaschine von ANL Plastics messen. ANL Plastics bewertet die Technologie von Hammer-IMS als schnell, robust, sicher, ökologisch und einfach zu installieren. Die Technologie wird als potenzieller Game-Changer für den Kunststoffverpackungsmarkt angesehen, da die Produkte von Hammer-IMS keine Kernenergie verwenden.