Low & Bonar, bekannt für die weltweit fortschrittlichsten Gewebetechnologien, entwickelt vielseitige Materialien in intelligenten Kombinationen, um Leistung zu bieten. Seit Mai 2020 Teil der deutschen Freudenberg Performance Materials, ist Low & Bonar Hückelhoven ein Pionier in der Gruppe der technischen Textilien. „Die erste gekaufte Installation innerhalb von Low & Bonar läuft jetzt seit mehr als 10 Monaten hier in Hückelhoven, Deutschland“, sagt Werksleiter Henk Hoekstra.

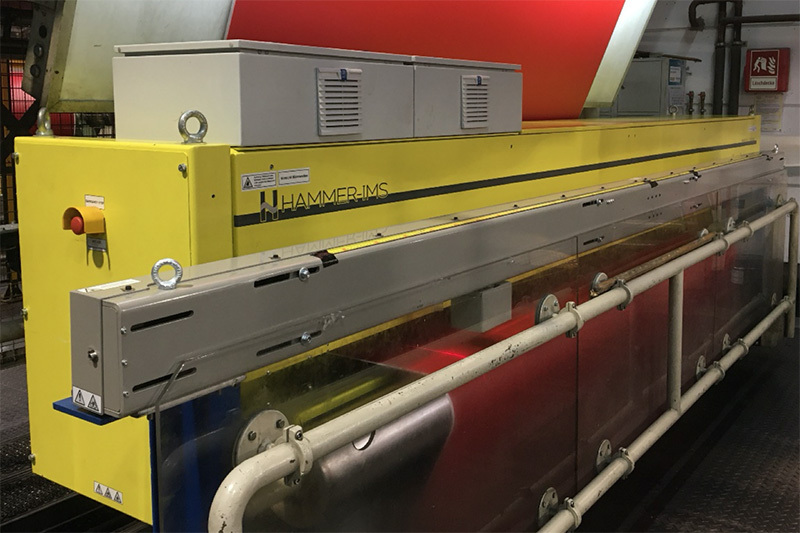

"Direkt hinter dem PVC-Kalandrierprozess auf unserer synthetischen Textillinie überprüft das Inline-System von Hammer-IMS das Flächengewicht der fertigen Produkte. Konsistente Grammatur wird durch das Scansystem sichergestellt, das mit mehreren M-Ray-Sensoren ausgestattet ist." Low & Bonar verwendet das System auf Stoffen mit einer Breite von bis zu drei Metern und Grammaturen, die von mehreren Hundert Gramm bis zu mehreren Kilogramm pro Quadratmeter reichen.

Während der Messung zeigt das Hammer-IMS-System die Messdaten dynamisch an und überträgt die Daten in eine Datenbank. Die Messergebnisse werden von Ulrich Volkmann aus der Abteilung Verfahrenstechnik überwacht. Die dynamischen Einblicke in die Qualitätskontrolle ermöglichen es Low & Bonar, eine hohe Qualität aufrechtzuerhalten oder schnell die Anforderungen nach Materialwechseln zu erreichen.

Low & Bonar optimiert die Produktivität, indem das System flexibel auf dünnen und dicken beschichteten Stoffen eingesetzt wird, darunter Planen, Zeltmaterialien usw. Es könnte sogar angewendet werden, um die Qualitätskontrolle bei Kunststoff-Zodiac-Außenteilen durchzuführen, was ebenfalls eine Aktivität von Low & Bonar ist.

Ein entscheidendes Kriterium für Low & Bonar war die Umweltfreundlichkeit der Hammer-IMS-Lösung. Das ausgewählte M-Ray-basierte System eliminiert alle Risikoabschätzungsverfahren und Sicherheitsvorkehrungen im Zusammenhang mit der Verwendung von radioaktiven oder nuklearen Systemen.

Henk Hoekstra hat einen visionären Ansatz dafür, wie das Hammer-IMS-System mit dem vorangegangenen Kalandrierprozess umgehen muss. Zu diesem Zweck bestellte Low & Bonar einen beweglichen Dual-Laserkopf von Hammer-IMS als Ergänzung, um die tatsächlichen Stellen zu visualisieren, an denen die M-Ray-Messungen stattfinden (siehe grauer horizontaler Strahl im Bild).

Low & Bonar Hückelhoven ist der erste Standort für die Gruppe der technischen Textilien von Low & Bonar. Ein zweites und drittes Hammer-IMS-Messsystem wurden bereits im Produktionswerk in Fulda, Deutschland, installiert. Auch in diesem Werk werden Messflexibilität und Effizienz qualitativ hochwertige Produkte von Low & Bonar gewährleisten, während gleichzeitig die Gesamtkosten des Eigentums dank der nicht-nuklearen Natur der Systeme weiter gesenkt werden.