Bilaterales internationales Abkommen zur Verbesserung des Beschichtungsgewichts in Veredelungslinien für gewebte, getuftete und nadelgestanzte Teppiche sowie Kunstrasen unterzeichnet.

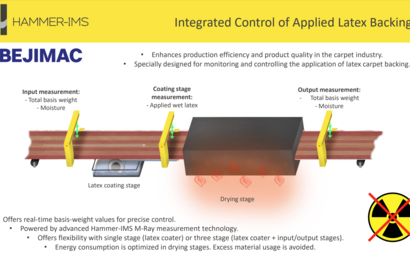

Die Tochtergesellschaft von Vandewiele, Bejimac, Spezialist für Textilveredelungsmaschinen, hat eine strukturelle Zusammenarbeit mit Hammer-IMS zur Qualitätskontrolle von Latexbeschichtungen etabliert. Dieses Abkommen passt in die gemeinsame Vision von Vandewiele, Bejimac und Hammer-IMS, die Veredelungslinien für Teppiche zu digitalisieren, wobei präzise, adaptive Messungen eine wesentliche Rolle spielen. Hammer-IMS integriert gezielt seine nicht-nukleare Technologie zur Messung des Beschichtungsgewichts in die Veredelungslinien von Vandewiele-Bejimac. Dank der Echtzeitmessung und automatischen Systemanpassung dieser intelligenten Systeme können Teppichhersteller die höchste Produktqualität beibehalten und gleichzeitig den Verbrauch und Abfall von teurem Latexmaterial reduzieren. Die Kooperationsvereinbarung sieht vor, dass Vandewiele seine Veredelungslinien, die mit Hammer-IMS-Technologie ausgestattet sind, vertreibt und verkauft. Diese Vertriebspartnerschaft umfasst die gesamte Welt, mit Ausnahme der EU, des Vereinigten Königreichs, Norwegens und der Schweiz.

Hammer-IMS hat ein Inline-Multi-Sensor-Qualitätskontrollsystem bei Toiltech in Frankreich installiert. Toiltech ist auf die Herstellung technischer und industrieller Textilien spezialisiert. Das Projekt wurde in Zusammenarbeit mit Erhardt+Leimer Frankreich eingerichtet, das Hammer-IMS in Frankreich vertritt.

ThermHex Waben verwendet eine nicht-nukleare und nicht-radioaktive Qualitätskontrollmaschine von Hammer-IMS. Das Inline-Scansystem mit drei Sensoren misst die Grammatur von thermoplastischen Verbundwabenplatten und Polypropylen-Wabenkernen. Darüber hinaus passt das System mit hohem Messabstand automatisch das Extrusionswerkzeug der Produktion an, um Grammaturvariationen auszugleichen. Die innovative Maschine von Hammer-IMS verbessert den Produktionsprozess und beseitigt menschliche Fehler in den Produkten von ThermHex Waben.

Natürlich ... wir sind immer mit unserer neuen Technologie in Bewegung. Aber dieses Mal ziehen wir unsere HQ-Büros um!

Seit Januar 2022 ist Max Bertram als Sales & Business Developer zu Hammer-IMS gestoßen. Es scheint, als denke Max international und habe verschiedene Kulturen erlebt. Hier ist ein kurzes Q&A, um Max ein wenig besser kennenzulernen.

In den kommenden Herbst- und Wintermonaten wird Hammer-IMS auf vier Veranstaltungen in ganz Europa ausstellen und/oder teilnehmen: Hofer Vliesstofftage in Hof (D), International Textile Coating & Lamination Congress in Gent (B), K-Messe in Düsseldorf und Global Insulation Conference & Exhibition in Estoril (P). Hammer-IMS wird eine Reihe von Lösungen zur Qualitätskontrolle präsentieren, die zahlreiche Innovationen integrieren und sofortige Rückmeldungen bieten, um Ihre Inline-Produktion zu steuern und zu optimieren.

After INDEX in Geneva last November, Hammer-IMS resumed its exhibition tour across Germany in Winter & Spring 2022. Many people came and visited us to watch one of our non-nuclear inline thickness and basis weight measuring systems in action! For example, the sleek and slim C-frame based system proves to be ideal for quality control of foils and films as well as coatings, paper, fabrics, textiles and nonwovens.

Sehen Sie sich unser neuestes Dual-Scansystem an, das als Inline-Projekt für PMC-Filze bei der Heimbach Gruppe (Olten, Schweiz) dient. Das automatisierte, auf M-Ray basierende System zur Qualitätskontrolle der Grammatur eliminiert radioaktive Quellen an dem, was der Kunde als Pre-Nadelwebstuhl bezeichnet. Wir haben mit Vansichen Linear Technology zusammengearbeitet, um ein fast 9 Meter langes Stahl-Linearmodul in einen sehr begrenzten, geneigten Raum einzupassen.

Vor einigen Monaten trat Joost Poelmans als R&D-Ingenieur dem Hammer-IMS-Team bei. Begrüßen Sie Joost, der Ingenieurwissenschaften studiert hat und an der Förderung der nicht-nuklearen M-Ray-Messung von Gewicht und Dicke mitarbeitet. Er führt auch intelligente Maschinenvision ein, um das Qualitätskontrollerlebnis für Hersteller von Kunststoffen, Textilien und Vliesstoffen weiter zu verbessern.

Mit vielen internationalen Systeminstallationen möchten wir darauf hinweisen, dass der Design-, Liefer- und Installationsprozess Ihrer Bestellung in guten Händen ist. Ihr Kauf bei Hammer-IMS ist eine kluge Entscheidung, nicht nur während wir daran arbeiten, Ihre glänzend gelbe Maschine pünktlich zu liefern, sondern auch wenn die Maschine in Ihrer gewünschten Produktionslinie in Ihrem Betrieb läuft.

Unsere disruptive M-Ray-Technologie ist von Natur aus rein elektronisch. Das bedeutet, dass unsere nicht-nuklearen Messlösungen harmlos für Menschen und die Umwelt sind. Vollständig sicher für die Bediener...

Immer wieder geben wir das Wort an einen unserer Kollegen bei Hammer-IMS. Heute kommentiert Nele Reynders, Senior R&D Engineer, die neuesten Entwicklungen im Maschinenbau für Messgeräte und die Integration von Messsystemen.